It’s a radiant morning at Rockwell Laser, where beams of precision and innovation intertwine to sculpt not just the landscapes of technology but the fabric of tomorrow. Amidst the hum of cutting-edge machinery and the glint of powerful lasers, there lies a story that scintillates with a promise—a promise to shape bright futures safely and responsibly.

Welcome to “Shaping Bright Futures: Laser Safety at Rockwell Laser,” where we’re about to embark on a journey through the heart of a company that champions pioneering advancements in laser technology while steadfastly prioritizing the well-being of its innovators and pioneers. Here at Rockwell Laser, safety isn’t merely a protocol; it’s a culture, a commitment woven into the very essence of every glowing beam that dances across our laboratories. Join us as we illuminate the principles, practices, and passionate people that ensure both brilliance and safety shine together in perfect harmony.

Table of Contents

- Ensuring a Safe Workspace: Foundations of Laser Safety

- Identifying Hazards: Common Laser Risks in the Industry

- Protective Gear Essentials: What You Need to Stay Safe

- Training to Excel: Building a Culture of Safety Awareness

- Routine Inspections: Keeping Laser Equipment in Check

- Q&A

- In Conclusion

Ensuring a Safe Workspace: Foundations of Laser Safety

In the luminous realm of lasers, ensuring the well-being of everyone in the workspace is paramount. At Rockwell Laser, we take pride in cultivating a safe and secure environment that allows innovation to thrive. Our comprehensive approach to laser safety is built on industry-leading practices and unwavering commitment to excellence.

- Risk Assessment: Every project begins with a thorough risk assessment, identifying potential hazards and implementing strategic controls.

- Training and Education: All team members undergo extensive laser safety training, ensuring they are well-informed about safe practices and emergency procedures.

- Proper Equipment: We invest in state-of-the-art protective equipment, from safety goggles to interlock systems, providing an added layer of security.

Our workspace is primarily designed to minimize risks associated with laser operations. We implement essential safety barriers and clear signage to alert and guide personnel. Regular safety audits ensure ongoing compliance and improvement. The collaborative spirit at Rockwell Laser emphasizes shared responsibility for a safe workplace, with open channels for reporting any concerns.

| Aspect | Details |

|---|---|

| Risk Assessments | Conducted monthly |

| Training Sessions | Quarterly |

| Equipment Checks | Weekly |

Empowering our team with knowledge and tools is just one part of our holistic approach to laser safety. Cultivating a culture of vigilance and proactive communication is equally crucial. From detailed simulations of potential incidents to accessible safety resources, every effort at Rockwell Laser is directed towards nurturing a safe, innovative, and collaborative environment.

Identifying Hazards: Common Laser Risks in the Industry

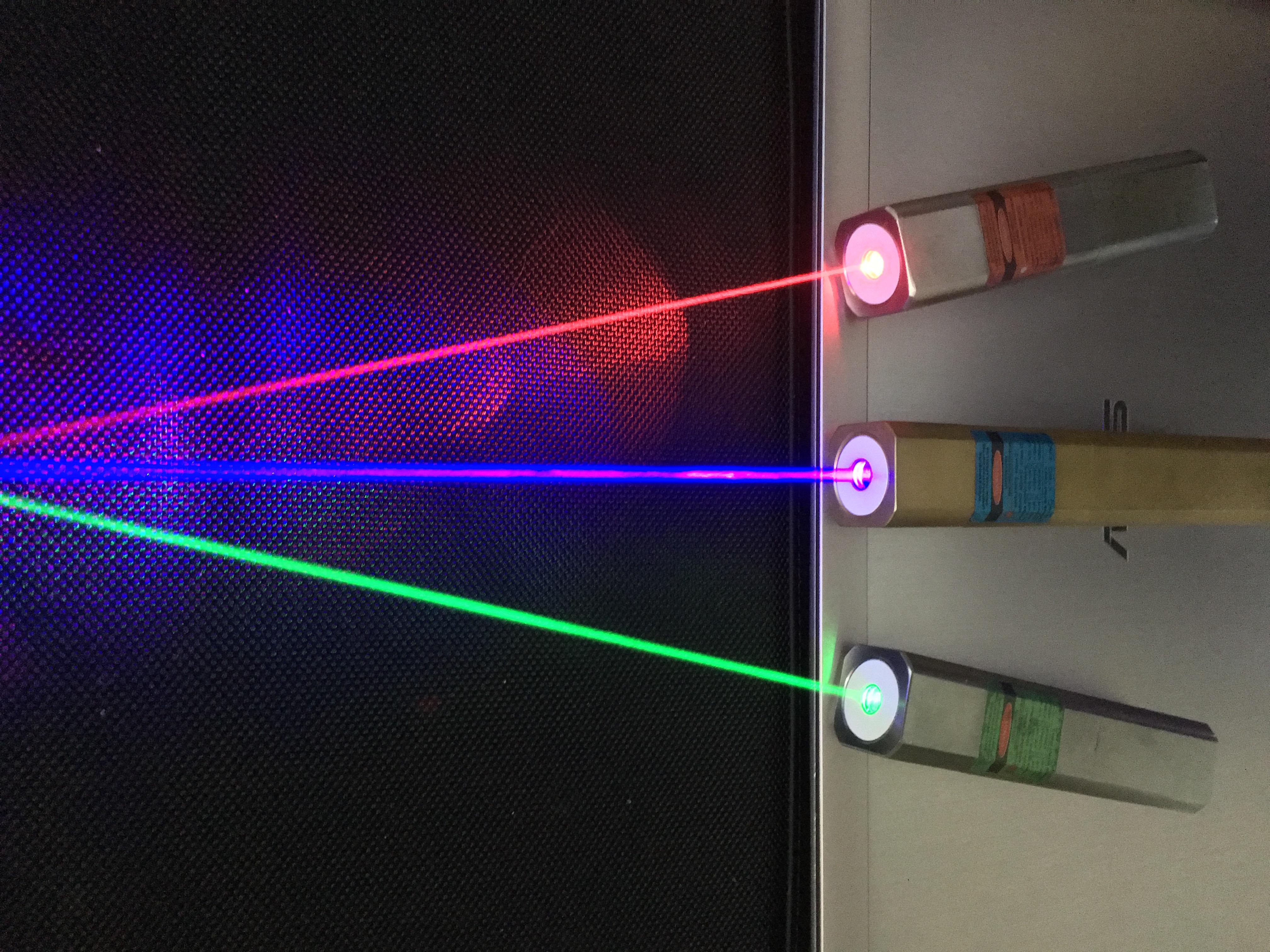

Ensuring laser safety is a cornerstone of our operations at Rockwell Laser. Among the most prevalent hazards we encounter in the industry are beam hazards. These risks arise from direct or reflected laser beams causing eye injuries or skin burns. Lasers of different classifications present varying intensity levels, with Class 4 being the most dangerous. It’s vital to use proper protective eyewear specifically designed for the wavelength of the laser in use.

- Class 1 and 2: Generally safe for incidental exposure.

- Class 3: Requires caution as direct exposure can cause injury.

- Class 4: High risk. Direct exposure is hazardous to eyes and skin.

Another significant risk is associated with non-beam hazards. This category includes chemical hazards (like fumes from cut materials), collateral radiation, and high-voltage electrical hazards that can be present in laser equipment. To combat these risks, we ensure all laser systems are installed with ventilation systems to manage fumes and that operators are trained to handle the equipment safely.

| Hazard Type | Description | Preventive Measures |

|---|---|---|

| Beam Hazard | Direct/Reflected beam causing eye/skin injuries | Use of protective eyewear, beam enclosures |

| Non-Beam Hazard | Chemical fumes, electrical risks | Proper ventilation, equipment handling training |

Ergonomic hazards can also arise from prolonged use of laser machinery. Extended periods of operation can lead to repetitive strain injuries (RSIs) given the meticulous tasks often required. Ensuring ergonomic workstations and encouraging regular breaks can mitigate these risks. At Rockwell Laser, we’ve designed ergonomically friendly workplaces for our team who work with laser equipment.

Lastly, environmental hazards such as the risk of fires cannot be ignored. Laser cutting and engraving can pose fire hazards, especially when flammable materials are involved. Implementing fire safety measures like keeping fire extinguishers nearby and conducting regular fire drills ensures everyone remains prepared and safe.

Protective Gear Essentials: What You Need to Stay Safe

Ensuring your safety while working with lasers involves a keen understanding of the essential protective gear required. Rockwell Laser prioritizes your vision by recommending high-quality laser safety glasses. These specialized glasses are designed to block or filter specific wavelengths of light, shielding your eyes from potential harm. Making sure you select the appropriate glasses tailored to the type of laser in use is crucial.

Another vital component is protective clothing. Working with lasers can expose you to potential burns or other skin injuries. A comprehensive protective outfit includes lab coats, gloves, and sometimes even full-body suits depending on the laser’s intensity and application. These garments should be made from materials that are not easily flammable and can effectively reflect or absorb laser radiation.

Ventilation systems and fume extraction devices are often overlooked but equally critical in maintaining a safe working environment. High-powered lasers, especially those used for cutting or welding, can produce harmful fumes and particles. A good ventilation system ensures the air remains clean and breathable, protecting your respiratory health.

| Protective Gear | Function |

|---|---|

| Laser Safety Glasses | Blocks harmful wavelengths |

| Protective Clothing | Prevents skin exposure |

| Ventilation Systems | Clears harmful fumes |

Proper signage and barriers also play a critical role in a laser-safe environment. Warning signs and designated laser operation areas marked with barriers ensure that only trained personnel access high-risk zones. Additionally, a well-marked area helps reduce accidental exposure and keeps unauthorized persons at a safe distance.

Training to Excel: Building a Culture of Safety Awareness

At Rockwell Laser, we believe that safety awareness is the backbone of our mission to innovate with integrity. The journey toward excellence in laser safety starts with our comprehensive training programs, which are designed to embed a culture of vigilance and responsibility in our teams. We understand that knowledge is our first line of defense, so we ensure every member, from engineers to administrative staff, is well-versed in safety protocols.

- Interactive Workshops: Regular, hands-on workshops that use real-world scenarios to prepare our teams for unexpected situations in the lab.

- Continuous Learning: Access to updated training materials and certifications through our proprietary Rockwell Learning Portal.

- Expert Guidance: Sessions conducted by experienced safety officers who bring years of practical knowledge to the table.

Incorporating safety practices into daily routines requires commitment and consistency. To foster this environment, we use a blend of traditional and modern educational tools, including e-learning modules and peer-to-peer mentoring. This not only aids in maintaining high safety standards but also reinforces a sense of community and shared responsibility within the organization. Our safety culture isn’t just about regulations—it’s about empowering every individual to take ownership of their well-being and that of their colleagues.

| Training Type | Frequency | Mode |

|---|---|---|

| Safety Induction | Onboarding | In-person |

| Monthly Refresher | Monthly | Online |

| Emergency Drills | Quarterly | In-person |

| Peer Review Sessions | Bi-annual | Hybrid |

Furthermore, feedback loops play a vital role in perpetuating a cycle of improvement. We have established channels for employees to voice their concerns, suggest enhancements, and share best practices. These inputs are instrumental in refining our training modules and safety protocols, highlighting our dedication to collaborative growth. Our mantra is clear: safety is not an endpoint, but an evolving process that we nurture every single day.

Routine Inspections: Keeping Laser Equipment in Check

Consistent monitoring ensures that the integrity and performance of laser equipment at Rockwell Laser remains impeccable. Our highly trained technicians run through a comprehensive checklist to identify any potential issues before they turn into costly repairs or safety hazards. Think of it as a health check-up for our laser systems—keeping them in optimal shape for your cutting-edge applications.

- Optics Inspection: Clean and clear optical components ensure precise laser output. Any signs of dust, scratches, or misalignment can drastically affect the beam quality.

- Calibration: Regularly calibrated equipment maintains accuracy and efficiency. This process verifies that the laser output meets the specified parameters, ensuring reliability.

- Cooling Systems Check: Proper cooling is essential to prevent overheating, which could lead to equipment failure. Routine inspection of cooling systems ensures they operate efficiently.

- Electrical Connections: Loose or corroded connections can cause malfunctions. Our inspection includes verifying the integrity of all electrical connections.

To keep track of our meticulous inspection process, we document everything in a detailed log. This log helps us maintain a history for each piece of equipment, providing valuable insights into its performance over time. Here’s a glimpse at a simplified version of our inspection log:

| Inspection Date | Component Inspected | Condition | Action Taken |

|---|---|---|---|

| 01/15/2023 | Optics | Clear | None |

| 01/15/2023 | Calibration | Accurate | Calibration Confirmed |

| 01/15/2023 | Cooling System | Operational | None |

| 01/15/2023 | Electrical Connections | Secure | None |

By adhering to our rigorous inspection schedule, Rockwell Laser ensures enhanced safety for both operators and equipment. This proactive approach minimizes downtime and prolongs the lifespan of our laser systems. It’s our commitment to you—ensuring that every beam of light from Rockwell Laser is one you can depend on.

Q&A

Q: What inspired Rockwell Laser to focus on laser safety?

A: At Rockwell Laser, we believe that the power of light can illuminate the future. Our inspiration stems from the desire to harness this power responsibly, ensuring that innovation doesn’t come at the cost of safety. By prioritizing laser safety, we aim to create an environment where cutting-edge technology can flourish without putting our team or the community at risk.

Q: How does Rockwell Laser make laser safety a top priority?

A: It’s a prism of practices! We start with comprehensive training programs for our team, ensuring they are masters of both innovation and safety. Every piece of equipment goes through rigorous safety checks, and our protocols are constantly updated to align with the latest industry standards. We also foster a culture of vigilance, where every employee feels empowered to voice concerns and contribute ideas to maintain our high safety standards.

Q: Can you share an example of a laser safety measure at Rockwell Laser?

A: Absolutely! One of our standout measures is the use of advanced laser safety goggles, designed to protect the eyes from potential exposure. These aren’t just any goggles – they are custom-fitted and regularly inspected to ensure maximum protection. Additionally, we’ve installed automatic shut-off systems that activate if a laser system is compromised, providing an extra layer of security.

Q: What role does employee training play in ensuring laser safety?

A: Employee training is the cornerstone of our safety strategy. We conduct regular workshops and certification programs that cover everything from basic laser physics to advanced safety protocols. Our training is not just a one-time event; it’s an ongoing process to keep our team up-to-date with new technologies and emerging safety practices. Because a well-informed team is our best defense against potential hazards.

Q: How does Rockwell Laser’s commitment to safety benefit innovation?

A: Safety paves the way for fearless creativity. When our team feels secure in their work environment, they are more likely to explore new ideas and push the boundaries of what’s possible with laser technology. By safeguarding our workspace, we not only protect our people but also foster a culture where innovation can thrive without hesitation.

Q: What advice would Rockwell Laser give to other companies regarding laser safety?

A: Our advice? Shine a light on safety and make it an integral part of your company culture. Invest in regular training, maintain your equipment rigorously, and encourage open communication about safety concerns. Remember, creating a safe environment is a collaborative effort, and when everyone is on board, the result is both a protected workforce and a fertile ground for innovation.

Q: How does Rockwell Laser involve the community in their safety practices?

A: Community engagement is key to our mission. We host public seminars and school visits to educate the broader community about laser safety. Our outreach programs are designed to demystify laser technology and emphasize the importance of safe practices. By extending our safety initiatives beyond our walls, we hope to inspire a wider culture of responsibility and awareness.

Q: What future plans does Rockwell Laser have in furthering laser safety?

A: Looking ahead, we’re excited to integrate even more advanced technology into our safety protocols, such as AI-driven monitoring systems for real-time hazard detection. We’re also expanding our training programs to include virtual reality simulations, offering immersive experiences that can better prepare our team for real-world scenarios. Our goal is to stay at the forefront of safety innovation, continually shaping a brighter, safer future for all.

Join us on our journey at Rockwell Laser, where safety and innovation go hand in hand to light the way forward!

In Conclusion

And so, dear reader, as we reach the end of our illuminating journey through the world of laser safety at Rockwell Laser, we hope that the brilliance of their commitment shines as bright as the beams they master. From the dedication of their team to the top-notch protocols that keep every pulse of light in check, Rockwell Laser is not just shaping technology – they’re shaping the future, responsibly and safely.

In a world where light can sculpt dreams and create realities, Rockwell Laser stands as a beacon of assurance, casting a promise that innovation and safety can indeed walk hand in hand. Here’s to the pioneers who work tirelessly behind the scenes, ensuring that every ray that breaks through the darkness is a step forward into a brighter, safer future.

May the lights of progress never dim, and may Rockwell Laser continue to lead the way – with precision, passion, and an unwavering commitment to safety. Until next time, keep your curiosity beaming and your ambitions laser-focused. Stay safe, stay inspired!