The familiar hum of a well-tuned engine is music to the ears of any automotive enthusiast. Whether you’re a seasoned mechanic or a weekend warrior, there’s an undeniable thrill in the power that roars to life beneath the hood. Yet, when that heart-pounding sound falls silent, it often points to an issue lurking deep within your vehicle’s core – the high torque starter and solenoid. Welcome to a journey where grease meets grit, as we demystify the essential steps to unleash your ride’s potential. Grab your tools, wear that winning smile, and let’s dive into the art and science of removing and replacing this pivotal duo, ensuring your car purrs with newfound vitality. Get ready to roll up those sleeves and power up for adventure!

Table of Contents

- Mastering the Mechanics: Understand Your High Torque Starter

- Tools of the Trade: Equip Yourself for Success

- Step-by-Step Guide: Safely Removing Your Starter & Solenoid

- Troubleshooting Tips: Avoid Common Pitfalls

- Pro Tips: Enhance Performance with a Perfect Installation

- Q&A

- Future Outlook

Mastering the Mechanics: Understand Your High Torque Starter

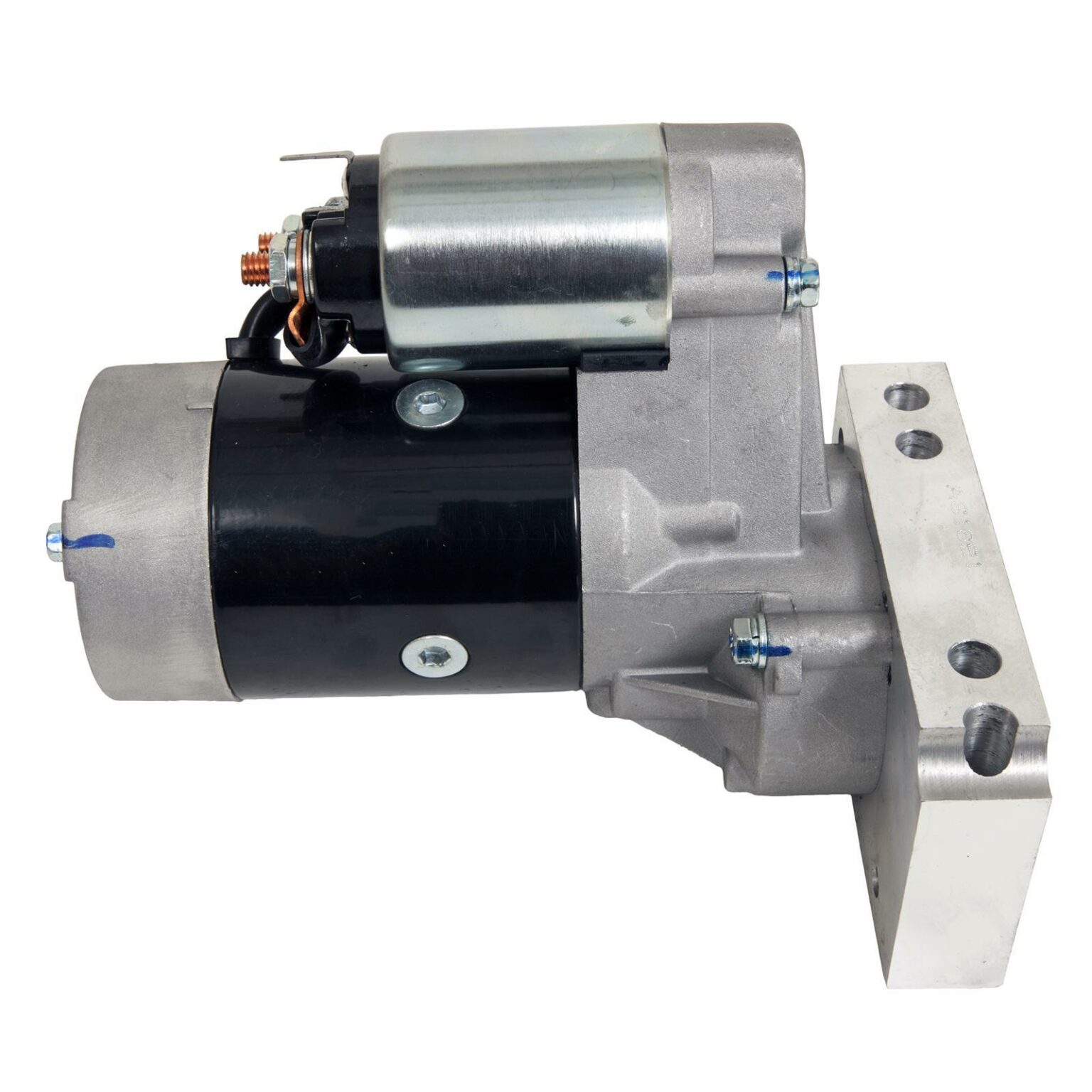

High torque starters are integral to high-performance engines, delivering the cranking power necessary to bring them to life. Understanding the intricacies of these mechanical marvels can drastically improve your vehicle’s efficiency and longevity. At their core, high torque starters are designed to offer more power with less rotational effort, making them ideal for engines with high compression or extensive modifications. By mastering these mechanics, you’re ensuring that your engine remains responsive and reliable, especially in demanding conditions.

Delving deeper, it’s crucial to recognize the significant components and their respective functions. This includes elements such as:

- Armature: The rotating part of the starter that transfers electrical energy into mechanical motion.

- Solenoid: The electromagnetic switch that activates the starter motor.

- Field Coils: These create the magnetic field necessary for the armature to generate motion.

Each of these parts plays a vital role in the high torque starter’s operation, and understanding their interactions can help diagnose potential issues and ensure optimal performance. Regular inspections and maintenance can preemptively address wear and tear, thus avoiding unexpected breakdowns.

Furthermore, when working with high torque starters, consider the differences in design and requirements compared to standard models. High torque starters often need upgraded electrical wiring and connections due to their higher power demands. For instance:

| Component | Standard Starter | High Torque Starter |

|---|---|---|

| Power Requirement | Low to Moderate | High |

| Wiring Gauge | 10-12 AWG | 8-10 AWG |

| Durability | Standard | Enhanced |

Choosing the right wiring gauge and ensuring the electrical connections can handle the additional power are critical steps in maintaining the starter’s efficiency and longevity. By understanding and accommodating these requirements, you’re setting the stage for a seamlessly powerful vehicle performance.

Tools of the Trade: Equip Yourself for Success

- Socket Set: Ensure you have a quality socket set on hand. Not only will it allow you to remove stubborn bolts securing the starter and solenoid, but a well-made set also reduces the risk of strippage and other complications. A ratcheting handle with a flexible head can make accessing tight spaces a breeze, saving you both time and frustration.

- Impact Wrench: High torque tasks call for power tools. An impact wrench provides the necessary force to loosen nuts and bolts that refuse to budge. Look for a model with adjustable torque settings to avoid over-tightening during reinstallation.

- Multimeter: Diagnose electrical issues with precision. A multimeter helps verify whether the starter or solenoid is receiving power, and its readings can guide your troubleshooting process, ensuring that you’re addressing the root cause of the problem rather than just the symptoms.

- Pry Bar: Useful when the starter or solenoid is particularly stubborn. A durable pry bar can help you gently but firmly dislodge components that seem welded in place by rust, grime, or time.

| Tool | Purpose | Features |

|---|---|---|

| Socket Set | Removing bolts | Variety of sizes, ratcheting handle |

| Impact Wrench | Unfastening tight bolts | Adjustable torque |

| Multimeter | Electrical diagnostics | Accurate readings, versatile settings |

| Pry Bar | Dislodging components | Durable, ergonomic handle |

Applying these tools effectively will simplify the challenging task of working with high torque starters and solenoids. The key is in the combination of precision and power. Pairing a socket set with an impact wrench covers both extremes, giving you the finesse needed for gentle work and the brute force when things get tough. A multimeter and a sturdy pry bar round out the toolkit, ensuring you are prepared for both electrical troubleshooting and mechanical manipulation.

Embrace the variety in your toolbox. Each tool plays a specific role, and understanding these roles will drastically reduce the time spent on each task while increasing your efficiency. The right equipment not only improves the quality of your work but also enhances safety, minimizing the risk of injury and mistakes. Remember, the journey to mechanical mastery is as much about preparation as it is about execution.

Step-by-Step Guide: Safely Removing Your Starter & Solenoid

Begin your journey by gathering all the necessary tools. **You don’t want to be in the middle of the job and realize you’re missing something essential.** Here’s what you’ll need:

- Socket wrenches and ratchets

- Screwdrivers (both flathead and Phillips)

- High-quality gloves

- Safety glasses

- Shop rags and cleaning supplies

Before you start, make sure your car’s battery is disconnected to avoid any electrical mishaps. It’s always better to work safe than sorry!

Finding the starter and solenoid is your next mission. **Usually, the starter is located near the bottom of your engine, attached to the transmission.** You may need to lift the car, so prepare your jack stands and creeper for a smooth glide under the vehicle. Check your car manual or follow the cable from the battery to locate the precise spot. Don’t forget to have a clean workspace, free from oil and grime, as it will make this mission cleaner and smoother.

Once you’ve identified the location, it’s time to get your hands dirty. **Start by removing the connecting cables first**, noting their positions for easy reinstallation. Disconnect the wires attached to the starter; there should be a large positive cable and a smaller ignition switch wire. Loosen and remove the bolts holding the starter in place with your socket wrench. Here’s a quick reference for the typical bolt sizes:

| Car Make | Bolt Size |

|---|---|

| Ford | 13mm |

| Chevrolet | 15mm |

| Honda | 10mm |

**Proceed with caution!** The starter can be heavy and awkward to handle. Make sure to have a clear path for removal.

With the starter out, the solenoid is usually attached directly. **Check your model specifics, but typically, you can remove the solenoid by unfastening a couple of screws or bolts.** Once removed, inspect the area for any signs of wear or damage. Clean the area using your shop rags and cleaning supplies. This is also a fantastic time to check other adjacent components for maintenance needs. Remember, a clean working environment reduces the risk of introducing contaminants back into your system when installing the new parts. Happy wrenching!

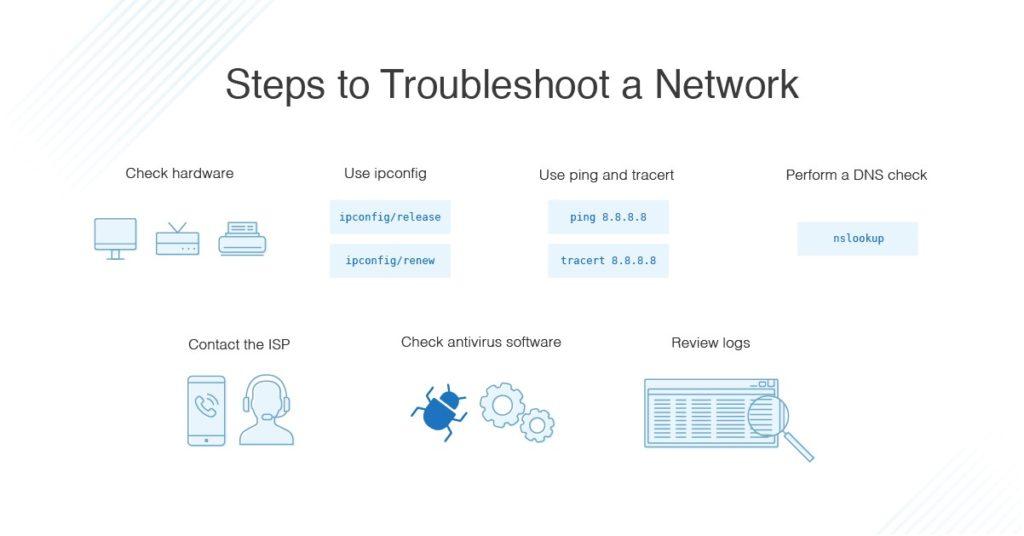

Troubleshooting Tips: Avoid Common Pitfalls

When tackling the task of removing a high-torque starter and solenoid, ensuring every step is executed with precision can prevent common issues. First and foremost, always disconnect the battery before beginning your work to avoid any electrical shocks. Using quality tools tailored for the job is just as important. **Cheap tools can strip bolts or cause damage**, leading to a more expensive repair than originally anticipated.

- **Disconnect the battery**: Essential for safety.

- **Use quality tools**: Prevents equipment damage.

- **Label wires**: Avoids mix-ups during reinstallation.

Labeling wires and connectors as you proceed is another golden rule. Nothing is more frustrating than reconnecting everything only to find it doesn’t start because a wire was misplaced. Use masking tape and a marker to mark each wire. A simple label such as “**starter solenoid positive**” or “**starter motor ground**” can save valuable time during reinstallation.

| Component | Action Needed |

|---|---|

| Battery | Disconnect |

| Wires | Label each connection |

| Tools | Use high-quality |

Treating your workspace with respect can also dramatically improve the process. **Ensure you have a clean, well-lit area to work**, reducing the risk of lost bolts or tools. It’s surprising how easily items can disappear in cluttered spaces. Furthermore, have a container on hand for bolts and small parts. By keeping all components organized, **you’ll save time and reduce frustration** when it comes to reassembly.

- **Clean workspace**: Reduces lost items.

- **Good lighting**: Prevents mistakes.

- **Parts container**: Keeps components organized.

If something seems off during reinstallation, never force parts into place. **High-torque starters are precision components**, and forcing things can damage delicate internals. If resistance is met, backtrack to ensure everything is aligned correctly. Sometimes the smallest misalignment can cause the greatest headache. Taking an extra moment to double-check can ensure a smooth and successful reinstallation.

- **Avoid forcing parts**: Prevents damage.

- **Check alignment**: Ensures smooth reinstallation.

- **Take your time**: Reduces errors.

Pro Tips: Enhance Performance with a Perfect Installation

Start by **selecting the right tools** for the job. Using high-quality tools ensures minimal wear and tear on both the starter and your vehicle. This includes:

- Torque wrenches – For precise settings.

- Socket sets – To fit various bolts and nuts.

- Safety gear – Gloves and goggles are a must.

It’s crucial to **prepare the workspace** appropriately. A clutter-free area allows for better maneuverability and less chance of accidents. Make sure you have:

- A flat surface – To prevent rolling parts.

- Good lighting – You’ll need a clear view.

- Organized workbench – Keep tools within easy reach.

| Item | Description |

|---|---|

| Torque Wrench | For precise torque settings |

| Socket Set | Various sizes to fit different bolts |

| Gloves | For hand protection |

| Goggles | To protect your eyes |

Before installing your new starter, make sure all **connections are clean** and free of corrosion. A wire brush can be handy here. Attach terminals securely and consider using dielectric grease to prevent future corrosion.

conduct a **final check** before you start your engine. This involves ensuring all bolts are tightened to the right specifications and verifying that electrical connections are stable. A quick once-over can save you from unexpected issues down the road.

Q&A

Q&A: Unleash The Power: Remove High Torque Starter & Solenoid

Q1: Hey! What’s this article all about?

Howdy, adventurer! This article dives into the heroic quest of removing a high torque starter and solenoid from your trusty ride. Think of it as your ultimate guide to reviving the heart of your machine—with a little elbow grease and a lot of gusto!

Q2: Why should I remove my high torque starter and solenoid?

Great question, road warrior! Just like knights needed to sharpen their swords, your ride’s starter motor and solenoid need to be in top-notch condition for sparkling starts and smooth rides. Over time, these components wear out, and replacing them can save you from unexpected breakdowns and breathe new life into your vehicle.

Q3: Do I need any special skills or tools for this job?

Fear not, brave soul! While you don’t need to be a seasoned mechanic, a bit of mechanical curiosity and the right tools—like wrenches, screwdrivers, and socket sets—will be your allies in this endeavour. Plus, our step-by-step guide will be your trusty map through the journey.

Q4: Is there a step-by-step process to follow?

Absolutely! We break it down like a treasure map:

- Prep Your Ride: Disconnect the battery—safety first!

- Locate and Access: Find your starter and solenoid, nestling near the engine.

- Unleash the Bolts: Carefully remove the bolts and wiring, noting their positions.

- Swap It Out: Install the new starter and solenoid, retracing your steps.

- Reconnect Everything: Secure all connections and bolts, and reconnect the battery.

Voilà! You’re ready to hit the road again.

Q5: Will this make my vehicle’s performance better?

You bet! A fresh starter and solenoid can make your ride’s start-up game strong and reliable, meaning fewer hiccups and more vroom-vroom action. It’s all about unleashing your vehicle’s full power potential!

Q6: What if I get stuck or something goes wrong?

No worries, champ! Even the best knights need a helping hand. If you hit a snag, consult a mechanic or automotive expert. There’s no shame in seeking backup to ensure the job is done right and your ride is road-ready.

Q7: Any last tips before I dive in?

Sure thing, fellow gearhead! Wear some gloves to protect your hands, take your time, and keep those nuts and bolts organized—nothing worse than a missing puzzle piece. And remember, this adventure is as much about the journey as the destination. Enjoy every twist and turn!

Q8: How do I know when it’s time to replace my starter and solenoid?

Excellent query! Indicators include a sluggish start, strange clicking sounds, or no crank at all. If your ride is resisting wake-up calls, it’s a sign your starter and solenoid might need a grand retirement.

Q9: Final thoughts?

Embark on this journey with confidence, wise road explorer! With a sprinkle of patience and our guide, you’ll master the art of starter and solenoid removal. Happy tinkering and safe travels—your adventure awaits!

Ready to unleash the power under your hood? Let’s get started, and may the torque be with you!

Future Outlook

And there you have it, fellow gearheads and weekend warriors! We’ve journeyed through the heart of your engine, delving deep into the intricacies of high torque starters and solenoids, emerging wiser and more empowered. By now, you’re armed with the knowledge to tackle this mechanical marvel, ready to unleash that hidden horsepower and hear your engine roar with vigor.

Remember, every nut and bolt tells a story of precision and patience. So, the next time your ride falters, don’t shy away. Roll up those sleeves, embrace the grease, and let your newfound expertise shine. After all, the road to mastery is paved with hands-on experience and a spark of curiosity.

Keep those engines purring smoothly, and until our wrenches cross paths again, happy tinkering and safe travels! 🚗💨