Have you ever been captivated by the mesmerizing dance of laser light? Whether slicing through rock concerts with dazzling beams, powering intricate surgical procedures with pinpoint precision, or enabling high-speed internet at blazing speeds, lasers are nothing short of magical. Today, we’re peeling back the curtain on one of the unsung heroes of the laser world: the diode laser. Prepare to embark on a journey through a world where technology meets enchantment, where light transforms to illuminate, create, and revolutionize. Welcome to “Shedding Light: Discover the Magic of Diode Lasers!” Here, the mysteries of these marvels of modern engineering will be unraveled, showcasing their incredible versatility and the broad spectrum of applications they illuminate. So, get ready to be dazzled as we delve into the story of how a tiny diode can harness the power of light to make the impossible possible!

Table of Contents

- Unveiling the Science Behind Diode Lasers

- Exploring the Versatility: Applications of Diode Lasers

- Mastering the Art of Precision: How Diode Lasers Work

- Choosing the Right Diode Laser for Your Needs

- Maintenance Tips to Keep Your Diode Laser Shining Bright

- Q&A

- Key Takeaways

Unveiling the Science Behind Diode Lasers

Imagine a world where light can be harnessed to create incredibly precise beams for surgery, high-speed internet, and even dazzling light shows. The secret to this magical light manipulation is the **diode laser**. Unlike traditional lasers, diode lasers rely on semiconductor materials to generate light, making them both versatile and efficient. But how do they achieve such feats of brilliance?

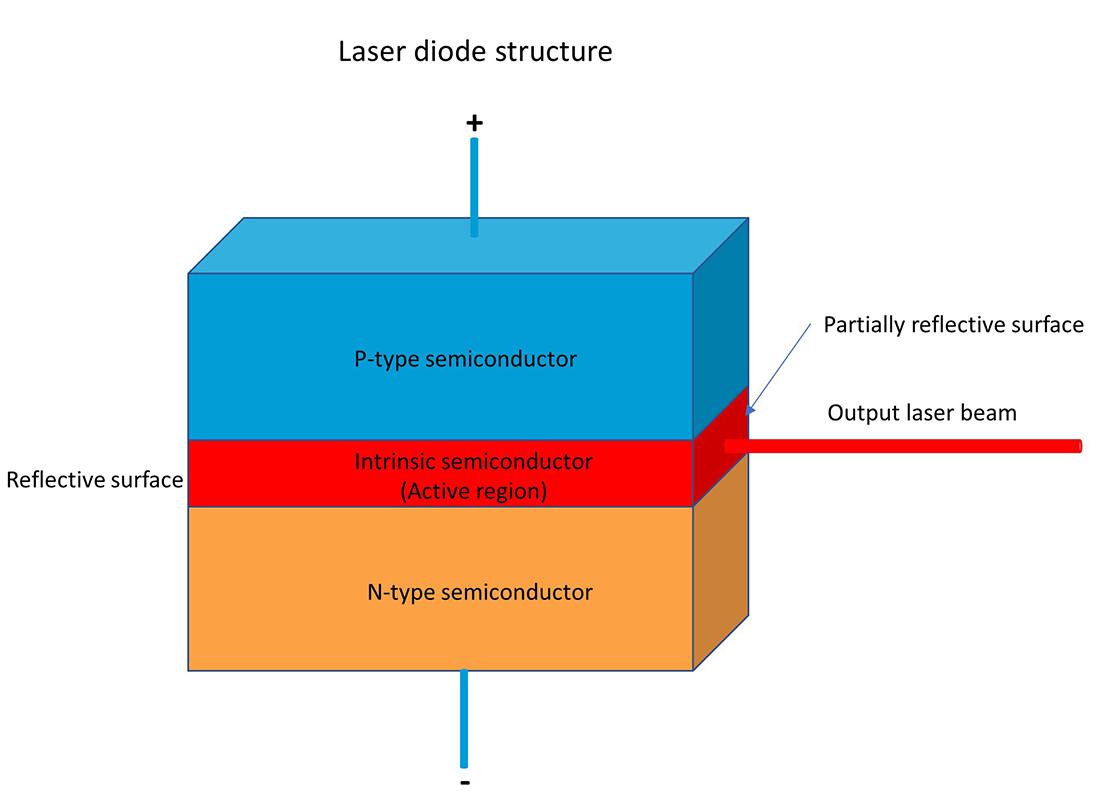

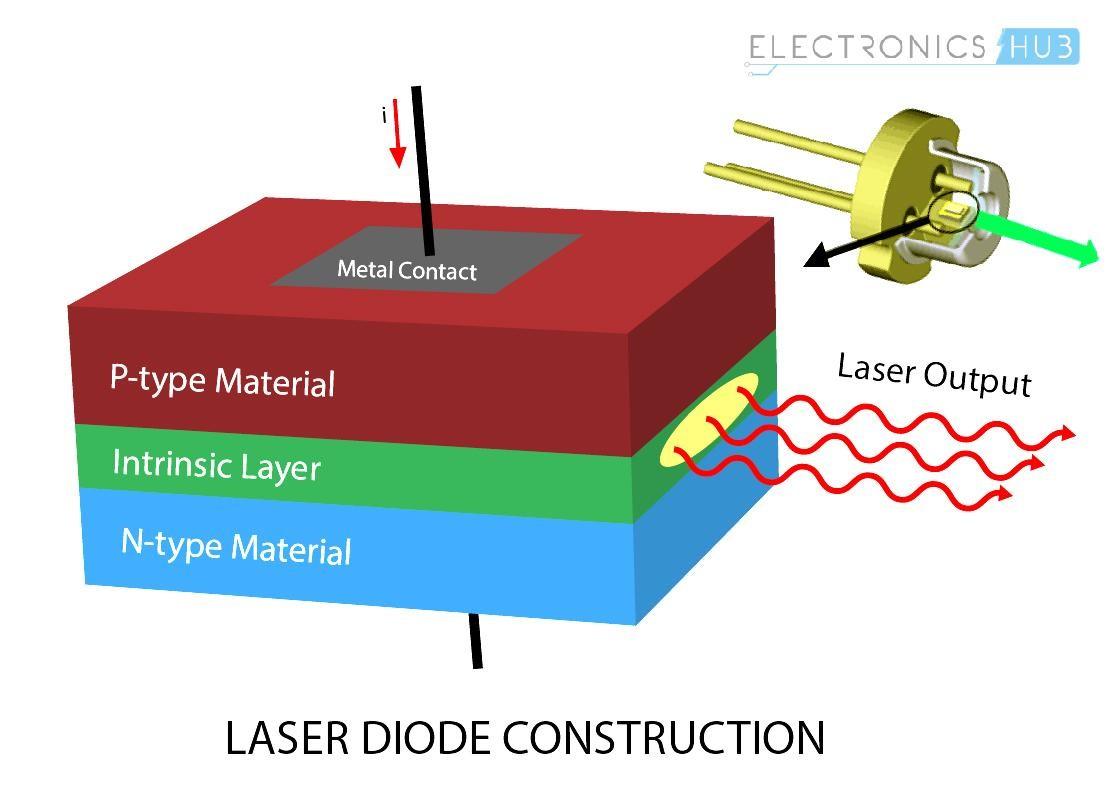

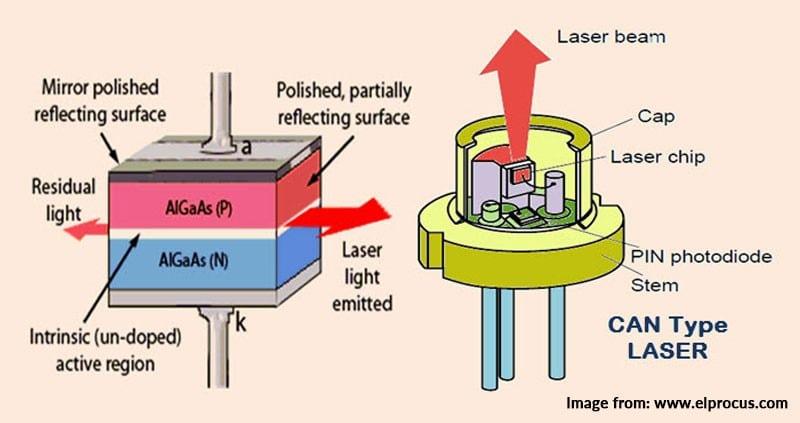

The heart of a diode laser lies in its p-n junction. This is the point where the p-type (positive) and n-type (negative) semiconductor materials meet, creating a depletion region. When a voltage is applied, electrons and holes (the absence of an electron) recombine at this junction, releasing energy in the form of photons. This process is known as **electroluminescence**. Small yet mighty, these photons are then amplified to produce a coherent light beam that is characteristic of lasers.

Diode lasers differ from other lasers in several key ways:

- Size: Compact and lightweight, making them suitable for portable devices.

- Efficiency: High electrical-to-optical efficiency, reducing power consumption.

- Wavelength Variety: Emission in multiple wavelengths, tailored for different applications.

These unique attributes make diode lasers indispensable in various fields, from telecommunications to medical diagnostics.

To better understand the technical specifications of diode lasers, let’s take a look at a comparison table that highlights the features of two popular diode laser models:

| Feature | Laser Model A | Laser Model B |

|---|---|---|

| Wavelength | 650 nm | 980 nm |

| Output Power | 50 mW | 100 mW |

| Application | Barcode Scanners | Fiber Optic Communication |

As seen in the table, the choice of wavelength and power levels can adapt diode lasers to different uses, showcasing their **adaptability** and performance. Indeed, diode lasers continue to open new frontiers in technology and science, proving that sometimes, the smallest components can create the most significant impacts.

Exploring the Versatility: Applications of Diode Lasers

The advent of diode lasers has heralded a new era in technology and innovation, offering tremendous versatility in their applications. These compact, efficient devices are making waves across a myriad of sectors, fundamentally changing the way we approach both everyday tasks and complex industrial applications. Diode lasers, with their miniature architecture and high performance, are nothing short of technological marvels.

Medical Fields: Diode lasers have gained prominence in medical applications due to their precision and ability to produce both high power and delicate performance levels. They are extensively used in:

- Ophthalmology – for corrective eye surgeries and retinal treatments.

- Dermatology – in laser hair removal, skin resurfacing, and tattoo removal.

- Dental Procedures – for soft tissue surgeries, reducing recovery times and minimizing discomfort.

Industrial Uses: In the realm of manufacturing and production, diode lasers are indispensable. Their utility ranges from material processing to intricate design applications. Key industrial uses include:

- Cutting and Welding – offering precision and efficiency in metal and plastic fabrication.

- Engraving – creating detailed designs on a variety of substrates.

- 3D Printing – facilitating the next generation of additive manufacturing techniques.

Consumer Electronics and Communication: Diode lasers play a crucial role in our daily lives, often in ways we do not even realize. They are at the heart of many consumer electronics and communication devices. Some example applications include:

| Application | Usage |

|---|---|

| CD/DVD/Blu-ray Players | Reading and writing data on discs |

| Bar Code Scanners | Enabling quick and accurate product scanning |

| Fiber Optic Communications | Facilitating high-speed data transmission |

Mastering the Art of Precision: How Diode Lasers Work

Imagine being able to etch intricate designs onto metal, or cut through materials with laser-like precision. Diode lasers empower makers and engineers to achieve such feats. At the heart of a diode laser lies a semiconductor device that transforms electrical energy into light. This process starts when electrons and holes within the semiconductor recombine, emitting photons. This light then builds up and reflects between mirrors, eventually emerging as a concentrated laser beam—an elegant solution for precision tasks.

The secret sauce for the functionality of diode lasers is in their **composition and architecture**:

- **Semiconductor materials**: Typically made of gallium arsenide (GaAs) or gallium nitride (GaN).

- **Recombination process**: Electrons drop energy levels, releasing photons.

- **Mirrors**: Positioned to reflect light back and forth to form a coherent beam.

Each component plays an essential role, contributing to the sharpness and focus of the laser beam.

Understanding the **operational dynamics** of diode lasers reveals more magic. The emitted light can be fine-tuned by altering electrical currents and the temperature of the diode. This adjustability makes diode lasers exceptionally versatile. For instance, low-power versions are used in barcode scanners, whereas high-power ones find applications in industrial cutting and medical surgeries. The wavelengths of the emitted light give further specificity to their usage, ranging from **visible light** to the **infrared spectrum**.

| Application | Power Level | Wavelength |

|---|---|---|

| Barcode Scanners | Low | Visible |

| Medical Surgeries | High | Infrared |

| Industrial Cutting | High | Visible/Infrared |

Choosing the Right Diode Laser for Your Needs

When it comes to **selecting the perfect diode laser** for your project, the options can be as diverse as the colors of the rainbow. Each type of diode laser brings a unique set of characteristics to the table. Whether you’re a do-it-yourself enthusiast, a professional in the medical field, or involved in high-tech manufacturing, finding the right fit is essential.

- Wavelength: The primary consideration for any diode laser is its wavelength. From the visible to the infrared spectrum, the wavelength determines what materials the laser can affect.

- Power Output: Match the laser’s power output with your project’s needs. Too high, and you risk overkill; too low, and you may not achieve the desired results.

- Beam Quality: A high-quality beam will ensure precision and efficiency, reducing waste and improving results.

Choosing between different diode types, such as **continuous wave** versus **pulsed diodes**, can greatly impact your application. Continuous wave diodes provide a constant beam, ideal for cutting or engraving, while pulsed diodes offer bursts of energy, making them perfect for medical procedures where precision is paramount.

| Feature | Continuous Wave Diodes | Pulsed Diodes |

|---|---|---|

| Beam Duration | Constant | Variable Pulses |

| Typical Uses | Cutting, Engraving | Surgery, LIDAR |

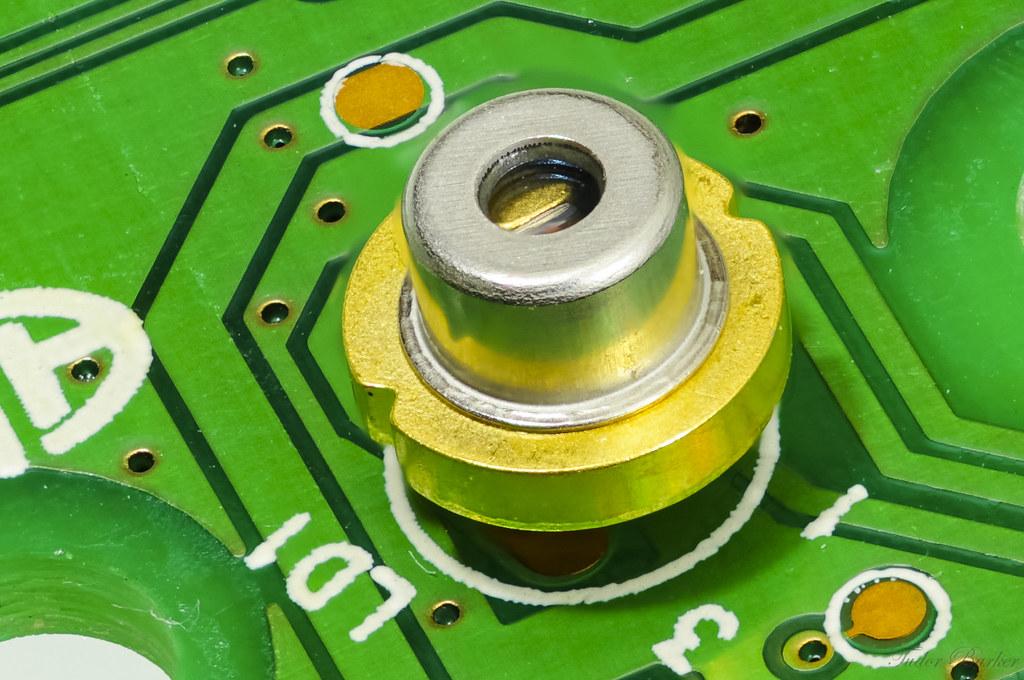

**construction quality and cooling mechanisms** are vital elements to assess. Diode lasers can generate significant heat, requiring efficient cooling systems to maintain performance and longevity. Seek out brands known for their durable build and reliable cooling solutions to ensure your investment stands the test of time.

Maintenance Tips to Keep Your Diode Laser Shining Bright

To ensure your diode laser continues to perform at its peak, regular maintenance is key. Think of it as a way to show some love to your beam of brilliance. Here are some essential tips that will keep your laser operating efficiently:

- Clean the Optics: Dust and debris can accumulate on the laser’s optics, potentially causing scattering and reducing output quality. Regularly use specific optic cleaning kits to gently wipe the laser lens.

- Check for Alignment: Misalignment can lead to poor laser performance or even damage. Ensure your laser beam is accurately aligned by performing routine checks and adjustments as needed.

- Temperature Control: Overheating can be detrimental. Make sure your laser operates within the recommended temperature range. Check cooling systems periodically to prevent thermal overloads.

- Power Supply Inspection: Consistent power supply is crucial. Monitor the power source and connections to prevent fluctuations that may impact the laser’s performance.

Consider setting up a maintenance schedule to stay on top of these tasks. Track when each maintenance activity was last performed and plan ahead for the next service. Here’s a quick example of a maintenance log table you could use:

| Maintenance Task | Last Performed | Next Due |

|---|---|---|

| Clean Optics | January 1st | February 1st |

| Check Alignment | January 5th | March 5th |

| Temperature Control | December 25th | February 25th |

| Power Supply Inspection | January 10th | February 10th |

Besides following these tips, always keep an eye on the manufacturer’s guidelines. These insights are tailored for your specific model and can provide additional nuances in care. Using manufacturer-recommended parts and accessories can also ensure that your diode laser performs optimally for a longer period.

don’t underestimate the value of professional servicing. Sometimes, having an expert evaluate and fine-tune your equipment can make all the difference. Schedule periodic professional check-ups to catch potential issues early and maintain that dazzling glow!

Q&A

Q&A: Unveiling the Wonders of Diode Lasers

Q: What exactly is a diode laser?

Diode lasers are like the wizards of the light world! They’re compact, highly efficient light sources that produce a coherent beam of laser light using semiconductor technology. Imagine tiny, high-energy fireflies that generate light in a very controlled and precise way.

Q: How are diode lasers different from other types of lasers?

While all lasers share the trait of emitting highly focused beams of light, diode lasers stand out because of their small size and versatility. Unlike bulky gas lasers or complicated solid-state lasers, diode lasers are like the Swiss Army knives of the laser family—compact, energy-efficient, and useful for a wide range of applications.

Q: Where can you find diode lasers in everyday life?

You probably encounter diode lasers more often than you think! They’re in the heart of every DVD and Blu-ray player, where they read your favorite movies and music. They light up optical fiber communication systems, enabling high-speed internet. They even assist in medical surgeries with precision that’s nothing short of miraculous.

Q: Why are diode lasers considered magical in the world of technology?

Their magic lies in their versatility and efficiency. Diode lasers can be tuned to emit different wavelengths, making them suitable for diverse applications—from cutting-edge scientific research to everyday consumer electronics. Plus, they convert electrical energy into light with minimal waste, making them marvelously efficient.

Q: Can diode lasers be dangerous?

Like any powerful tool, diode lasers should be used responsibly. Their focused beams can be harmful to the eyes and skin if not handled properly. But don’t worry—most consumer devices have safety mechanisms to protect you from accidental exposure to harmful laser light.

Q: How are diode lasers used in medicine?

Diode lasers have revolutionized the medical field! They’re used in delicate procedures like eye surgeries, where precision is crucial. They also play a role in dermatology, pain relief, and even dental treatments. Think of them as the dazzling, tiny scalpels of the future!

Q: What’s on the horizon for diode lasers?

The future is bright—literally! As technology advances, diode lasers are expected to become even more efficient and powerful. Researchers are exploring their potential in quantum computing, space communication, and advanced manufacturing. We’re just scratching the surface of their capabilities!

Q: Can you give an example of a creative use of diode lasers?

Certainly! Artists and designers have begun using diode lasers for spectacular light shows and intricate laser cuttings. Imagine a laser light show at a concert that syncs perfectly with the music, or a beautifully intricate art piece cut with laser precision. The creative possibilities are as limitless as your imagination!

So, whether you’re a tech enthusiast, a curious learner, or just someone who loves a good light show, diode lasers are here to ignite your inspiration. Embrace the magic and let the light guide your journey!

Key Takeaways

As we part ways on this luminous journey through the wonders of diode lasers, it’s clear how these tiny, radiant marvels have sparked a revolution in our world. From transforming medical treatments to powering next-gen tech gadgets, diode lasers have woven their magic into the very fabric of modern innovation. So, the next time you spot a laser beam slicing through the air or think about precision tools and devices, remember the dazzling diode behind the scenes, working its enchanting magic.

Thank you for joining us on this illuminating adventure. Keep your curiosity bright and let the light of knowledge guide you to ever more extraordinary discoveries!

Stay curious, stay brilliant. Until next time! ✨🔦🌟