In the bustling world of laser technology, two titans stand tall, casting their brilliant beams across an array of industries—CO2 lasers and diode lasers. Picture this: one brims with the storied legacy of yesteryears, its fiery beam cutting through materials like a hot knife through butter since the disco days of the 1970s. The other, a sleek and efficient modern marvel, promises precision and adaptability, embodying the spirit of the 21st century. So how did we get here, and what draws today’s innovators to one light over the other? Welcome to “CO2 vs Diode Lasers: Uncovering the Time Warp Tale,” where we’ll embark on a journey through time, technology, and a touch of friendly rivalry. Buckle up, and let’s unravel the story of these luminous legends.

Table of Contents

- The Origins: A Journey Through Laser Time

- CO2 Lasers: The Workhorses of Precision

- Diode Lasers: Compact Powerhouses for Modern Needs

- Comparative Analysis: Strengths, Weaknesses, and Applications

- Choosing Your Laser: Expert Tips for Making the Right Decision

- Q&A

- Concluding Remarks

The Origins: A Journey Through Laser Time

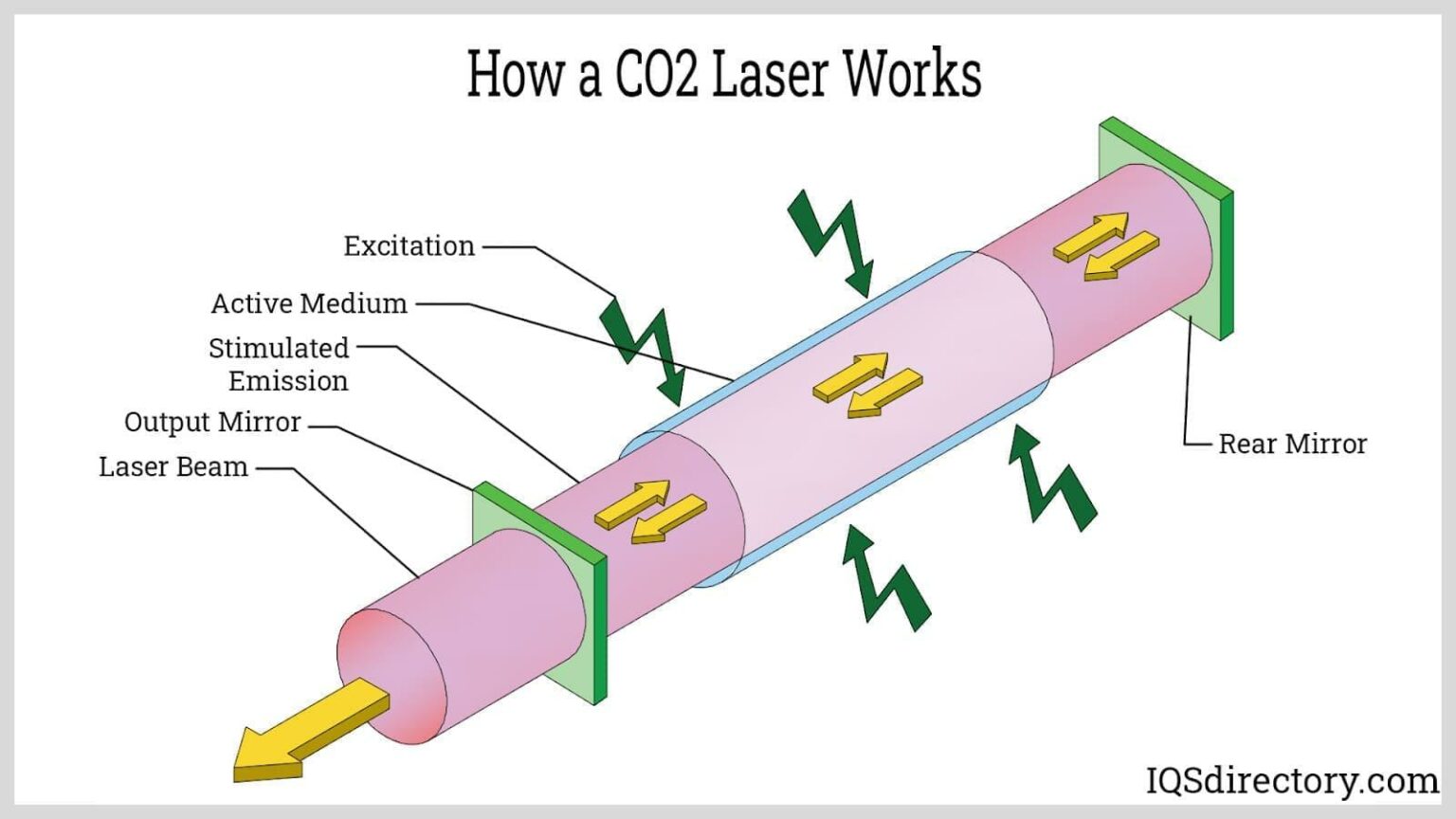

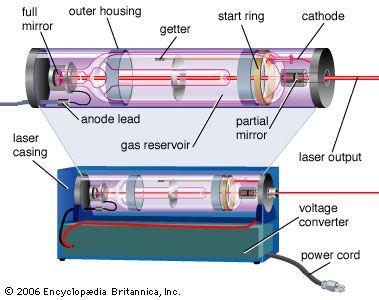

As we embark on this laser-fueled journey, we must first travel back to the dawn of laser technology itself. **CO2 lasers**, birthed in the vibrant waves of 1964’s scientific breakthroughs, were like the rockstars of their time—powerful, versatile, and a tad bit unruly. These lasers employ carbon dioxide gas as their lasing medium, producing an invisible light that dances in the far-infrared spectrum. Their strength? Cutting through materials like butter: metals, ceramics, and even some of the toughest polymers known to man.

- Discovery Year: 1964

- Wavelength: 10.6 micrometers

- Primary Use: Cutting, welding, engraving

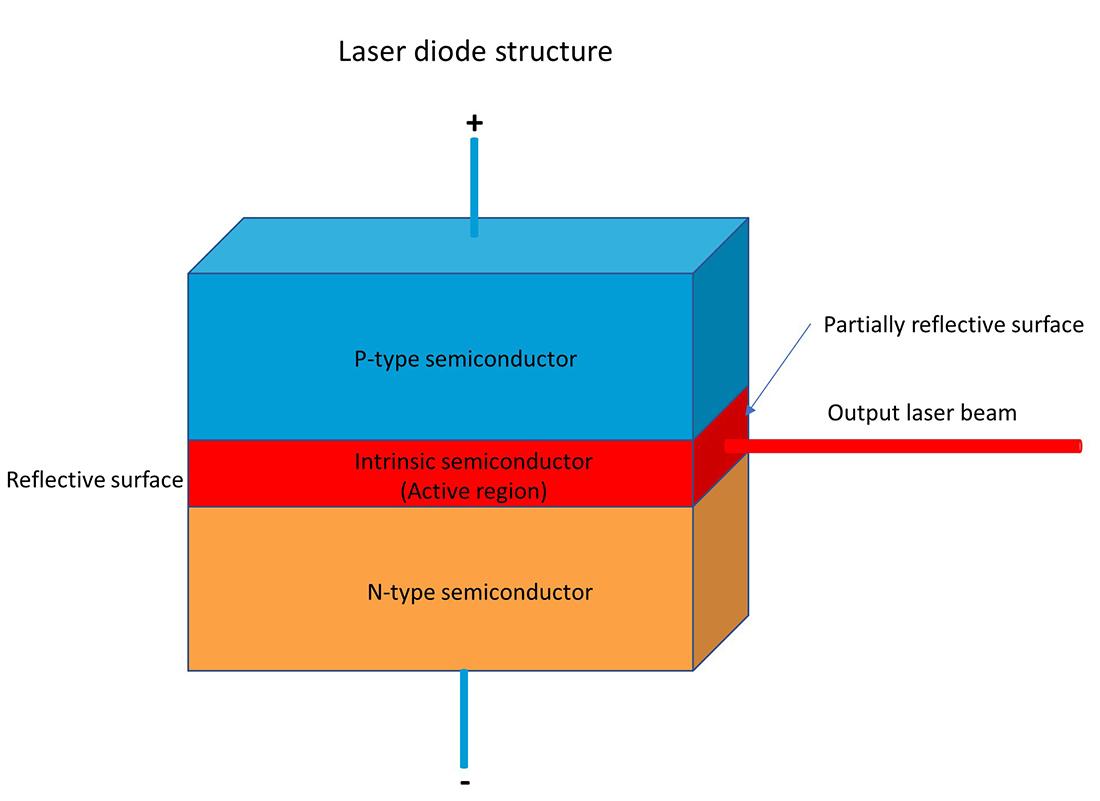

Fast forward to the disco era of the 1980s, and enter the **Diode lasers**—the more refined, compact, and efficient newcomers. Unlike their larger CO2 cousins, these lasers use semiconductor diodes as their lasing medium. This innovation brought several advantages to the table: mobility, affordability, and ease of integration into everyday gadgets and sophisticated medical equipment.

- Discovery Year: 1962 (commercialized: 1980s)

- Wavelength: Varies (commonly 800nm – 980nm)

- Primary Use: Optical communication, medical devices, consumer electronics

| Aspect | CO2 Lasers | Diode Lasers |

|---|---|---|

| Power | High | Moderate |

| Size | Large | Compact |

| Cost | Expensive | Affordable |

As you can see, these two pioneering laser types have carved out distinct niches in the temporal ledger of technology. While CO2 lasers dominate the world of industrial applications, slicing through objects with Herculean strength, Diode lasers charm us with their user-friendly nature and adaptability. Both have propelled numerous innovations, and though separated by time, they coexist in a symphony of light, shaping our present and illuminating the future.

CO2 Lasers: The Workhorses of Precision

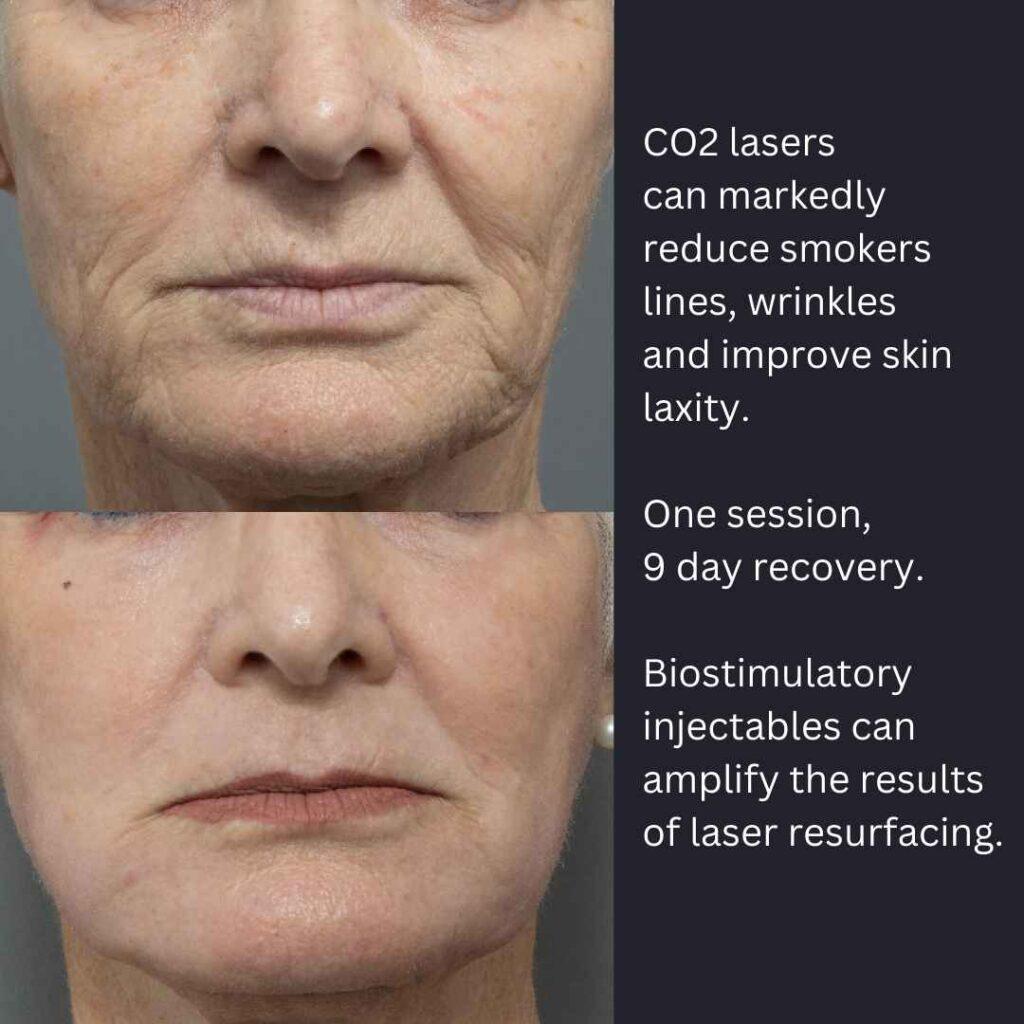

CO2 lasers have long been heralded as the quintessential tools for tasks demanding extreme precision. Their ability to slice through materials with unfaltering accuracy transcends the mundane, revealing a spectrum of applications that render them indispensable in various industries. Whether crafting intricate designs in the fashion world or facilitating delicate surgical procedures, these lasers seamlessly fuse innovation with functionality, proving their mettle time and time again.

Imagine the delicate dance of light as CO2 lasers work their magic. Their capacity to cut, engrave, and weld with unparalleled efficiency has positioned them as stalwarts in fields ranging from **aerospace engineering** to **medical instrumentation**. They thrive on tasks that require meticulous attention to detail, ensuring every cut is nothing short of perfection. It’s this unwavering reliability that sets them apart, making them the go-to choice for professionals who refuse to settle for anything less than the best.

In addition to their precision, CO2 lasers offer impressive versatility. Here are some standout attributes:

- High power levels: Ideal for cutting thicker materials.

- Perfect beam quality: Ensures clean and precise cuts.

- Material compatibility: Can work with metals, plastics, glass, and even organic materials.

- Longevity: Designed for rigorous long-term use.

| **Feature** | **CO2 Lasers** |

|—————-|——————————–|

| **Cutting Depth** | Up to 20 mm on certain materials |

| **Beam Quality** | Superior |

| **Material Range** | Extensive (metals, non-metals) |

| **Operational Cost** | Moderate |

In essence, the meticulous craft of CO2 lasers has made them the undisputed champions of precision work. Their ability to perform with consistent excellence underscores their role as industry titans. For artisans, engineers, and medical experts alike, these lasers are not just tools—they are trusted partners in the quest for perfection.

Diode Lasers: Compact Powerhouses for Modern Needs

When it comes to innovative and versatile solutions in the realm of laser technology, diode lasers are rapidly climbing the ladder. Small yet mighty, these devices are gaining popularity for their unmatched efficiency and flexibility. Boasting compact forms and impressive power outputs, they have a variety of modern applications, from precision cutting in industrial settings to intricate medical procedures. With minimal warm-up times and exceptional energy efficiency, diode lasers are truly the unsung heroes of modern laser technology.

- Energy Efficiency: Diode lasers convert electrical energy into photon energy with remarkable efficiency, often surpassing other types of lasers in this aspect.

- Compact Design: The small form factor makes them easily integrable into various devices and even handheld tools.

- Versatility: They can be used in a plethora of fields such as telecommunications, medicine, and material processing.

A comparison between the modern diode lasers and the more traditional CO2 lasers reveals fascinating contrasts. CO2 lasers have been the workhorses of the industry for decades, especially in cutting and engraving thick materials. However, diode lasers have caught up rapidly and now offer some competitive advantages that are hard to overlook. For instance, while CO2 lasers might require more maintenance and intricate cooling systems, diode lasers often operate efficiently with simpler air or water cooling mechanisms.

| Feature | Diode Lasers | CO2 Lasers |

|---|---|---|

| Size | Compact | Bulky |

| Maintenance | Low | High |

| Cooling | Air/Water | Complex |

The sustainability aspect also places diode lasers a step ahead. Due to their energy-efficient nature, they have a smaller carbon footprint compared to CO2 lasers. Additionally, their longevity and decreased need for replacements or repairs make them an eco-friendly choice. Imagine moving towards a future where even our most powerful tools leave minimal impact on the environment, all while maintaining robust performance and versatility. Diode lasers could be the compact powerhouses driving us towards that future.

Comparative Analysis: Strengths, Weaknesses, and Applications

When delving into the world of laser technology, it’s essential to understand the contrasting **strengths** and **weaknesses** of CO2 and diode lasers. CO2 lasers, renowned for their continuous wave capabilities, excel at cutting and engraving materials such as acrylic, wood, and fabric. Their knack for handling non-metallic materials with precision makes them a favorite in various industries. Conversely, diode lasers, with their compact size and high efficiency, shine in the realm of marking and engraving metals like aluminum and steel, presenting a different spectrum of applications.

- CO2 Lasers Strengths: High cutting speed, versatility with non-metals.

- Diode Lasers Strengths: Compact size, energy-efficient, excellent for metal marking.

The **weaknesses** of these lasers are grounded in their specialized natures. CO2 lasers, despite their prowess on non-metals, struggle with metals due to their wavelength absorption characteristics. On the other hand, diode lasers, while efficient and metallically versatile, often face limitations in power output and depth of cut when dealing with thicker materials. A distinct drawback for each, yet essential in steering users toward the right choice for their needs.

| Criteria | CO2 Lasers | Diode Lasers |

|---|---|---|

| Material Compatibility | Non-Metals | Metals |

| Power Efficiency | Moderate | High |

| Size | Large | Compact |

In terms of **applications**, both lasers find niches where they masterfully outperform traditional methods. In **industrial manufacturing**, CO2 lasers create intricate cuts and engravings on customized products like signage and prototypes, offering unmatched detail. Meanwhile, diode lasers etch serial numbers, barcodes, and logos onto metal surfaces swiftly, a boon for **inventory management** and **brand protection**. Understanding these dynamics not only highlights the strengths and weaknesses but also ensures that the right tool is employed for the task at hand.

The realm of **creative arts** and **personalized products** expands further with these laser technologies. CO2 lasers create delicate patterns on wooden and acrylic ornaments, perfect for bespoke gifts and intricate art pieces. Diode lasers lend themselves to custom engravings on jewelry and metal memorabilia, ensuring that each piece carries a lasting personal touch. These applications underline the transformational power of these technologies, weaving efficiency and creativity seamlessly into the fabric of modern innovation.

Choosing Your Laser: Expert Tips for Making the Right Decision

When it comes to selecting the right laser for your projects, you’re essentially stepping into a time machine, navigating an intricate labyrinth of choices that can make a significant impact on your final results. Let’s break down the complexity to something more digestible. **CO2 lasers** and **Diode lasers** are the two primary players in this adventure. Each has its unique attributes, akin to characters in an epic tale.

Consider your hero — the **CO2 laser**. It wields a powerful 10.6-micron wavelength that can cut through diverse materials like an enchanted sword slicing through anything in its path. With an uncanny ability to handle **wood, leather, acrylic, and even some metals**, it’s the go-to choice for versatility. However, its complexity and need for meticulous maintenance might feel like mastering an age-old sorcery — powerful but demanding.

Then we have the **Diode laser** — the underdog with a radiant charm. Its 445-nanometer wavelength is more subtle yet remarkably effective. Perfect for engraving and marking on **plastics, metal coatings, and some stone types**, the Diode laser is often appreciated for its user-friendly interface and reduced upkeep. Think of it as the loyal sidekick who’s always ready for action but doesn’t require a multitude of spells to keep in check.

| Features | CO2 Laser | Diode Laser |

|---|---|---|

| Wavelength | 10.6 microns | 445 nanometers |

| Best For | Wood, Leather, Acrylic, Some Metals | Plastics, Metal Coatings, Some Stones |

| Maintenance | High | Low |

To make an informed decision, consider what quests you undertake most frequently. If versatility is your guiding star and you don’t mind the learning curve, the CO2 laser might just be your Excalibur. However, if you prefer a more straightforward approach with less maintenance, the Diode laser can be your trusty, uncomplicated companion. All adventures, of course, are shaped by the paths we choose, and so is your laser journey.

Q&A

Q: What’s with the whole “Time Warp” in the title?

A: Great question! The “Time Warp” isn’t about hopping into a time machine (although that would be cool). It’s more about the incredible journey and evolution of laser technology over time. Both CO2 and diode lasers have distinct punctuated chapters in this technological timeline, reflecting advancements and changing industrial needs. It’s like comparing two timelines in the sci-fi world of lasers!

Q: So, what are the key differences between CO2 lasers and diode lasers?

A: Alright, buckle up! CO2 lasers are like the wise elders of the laser realm. They’ve been around for decades and are well-known for their precision in cutting and engraving metals, wood, glass, and even fabrics. They emit light at a wavelength of 10.6 micrometers, making them perfect for materials that absorb this wavelength well.

Diode lasers, on the other hand, are the sleek, modern descendants. They’re highly efficient, compact, and versatile. With wavelengths typically ranging from 780 to 980 nanometers (or into the deeper infrared), they’re perfect for applications like cutting thin metals, medical treatments, or even your everyday CD player.

Q: How do energy efficiency and maintenance compare between them?

A: CO2 lasers, being the veterans, require a bit more TLC. They have more components that can wear out, like gas tubes, mirrors, and cooling systems. They also tend to consume more power, so they might not be the eco-warriors of the laser world.

Diode lasers, on the other hand, are like the low-maintenance friends everyone loves. They’re solid-state devices with fewer parts that can break down, which means less upkeep. Plus, they shine brilliantly in the energy efficiency department, converting much more electrical energy into useful laser light. Your wallet and the planet say thank you!

Q: What’s the buzz about their applications?

A: CO2 lasers have their fanbase in the manufacturing and engraving sectors. Think of them as the Dumbledores of cutting and engraving, handling metals, woods, plastics, and ceramics with spellbinding precision.

Diode lasers? They’re the versatile Swiss Army knives of the laser world. They clearly shine in the medical field for procedures like laser skin treatments and eye surgeries, and they’re also picking up steam in telecom, defense, and even as the teeny-tiny sensors in your smartphone.

Q: Are there any cutting-edge trends we should know about?

A: Oh, absolutely! For CO2 lasers, the trend is all about increasing automation and integrating with other tech, like AI and IoT, to make manufacturing smarter and more efficient.

Diode lasers are on a miniaturization spree. They’re getting smaller, more powerful, and being integrated into devices like LIDAR for autonomous vehicles and advanced optical communication systems. They’re basically the evolving superheroes of the laser saga!

Q: If I had to choose, which laser should I go with?

A: Ah, the ultimate question! It really depends on what you need. For heavy-duty cutting and engraving of a variety of materials, a CO2 laser is your steadfast ally. But if you’re looking for something that’s nimble, highly efficient, and versatile with a tendency toward high-tech applications, you can’t go wrong with a diode laser.

Think of it as picking between Gandalf and Iron Man—both are awesome in their own right, but your choice depends on the adventure you’re embarking on!

Q: Can both these lasers coexist, or is this a Highlander situation?

A: Thankfully, it’s not a “there can be only one” scenario! Both CO2 and diode lasers have their unique strengths and roles, complementing each other in the vast landscape of laser technology. They coexist beautifully, each shining in their respective domains and driving innovation forward in ways that are nothing short of stellar!

Concluding Remarks

And there it is—the grand tale of CO2 and diode lasers, a saga filled with ancient wonders and cutting-edge marvels. From the nostalgia-laden hum of CO2 lasers evoking the golden age of industrial innovation, to the sleek, space-age precision of diode lasers guiding us into a future brimming with possibilities, our journey has straddled decades of technological triumph.

From the meticulous craftsmanship required to tune a CO2 laser’s beam for intricate artwork to the nimble adaptability of diode lasers making waves in medical surgeries, we’ve seen how each has staked its claim in the annals of laser history. Both have their quirks and merits, their loyal followers and ideal applications—just like heroes in an epic adventure.

As you step away from this tale, remember that whether you find yourself drawn to the time-tested robustness of CO2 lasers or the modern elegance of their diode counterparts, the choice is yours. Each laser type brings a unique set of capabilities to the table, ready to captivate imaginations and drive innovation.

So, fellow explorer, as you ponder your next laser-based conquest, know that you are armed with the wisdom of the ages and the foresight of future tech. May your paths be clear and your beams ever precise, as you cut, engrave, and etch your own legacy into the fabric of time.

Until our next journey through the corridors of technology, stay curious, stay inspired!

Safe travels through the time warp.