Picture this: a beam of light so focused it can perform delicate eye surgery, slice through steel, or even dazzle dancers on a nightclub floor. Lasers have long transcended the realm of science fiction, embedding themselves in our everyday reality with their futuristic allure. Yet, with great power comes great responsibility, and the journey from curious illumination to precision tools carries its fair share of risks.

Welcome to “Lasers with Care: Navigating Safety and Hazard Zones,” where we shine a light (pun absolutely intended) on the essential guidelines and precautions necessary to harness these potent beams safely. Whether you’re a laser enthusiast, a seasoned professional, or someone simply intrigued by the magic of coherent light, join us as we delve into the dos, don’ts, and everything in between. It’s time to navigate the fascinating yet perilous landscape of laser safety with equal parts curiosity and caution. Let’s illuminate our path forward, together.

Table of Contents

- Understanding Laser Classifications: Know Your Beam

- The Dos and Donts of Laser Safety

- Creating Safe Work Environments with Laser Equipment

- Essential Gear: Protective Eyewear and Beyond

- Managing Laser Accidents: Quick Response and Prevention Tips

- Q&A

- Closing Remarks

Understanding Laser Classifications: Know Your Beam

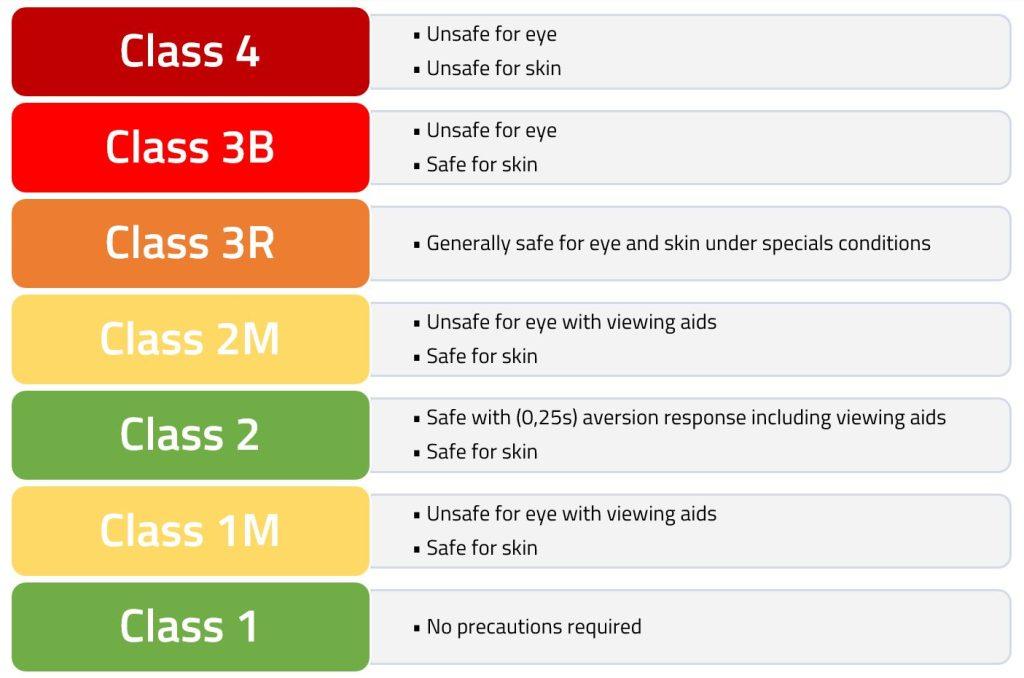

When dealing with lasers, it’s crucial to recognize the varying levels of power and potential hazard they possess. Laser classifications were established to provide a clear understanding of the safety measures required for each type. The most common classifications range from Class 1 to Class 4, each with its own set of guidelines and safety protocols.

**Class 1** lasers are considered safe under all conditions of normal use. These lasers pose no danger to the eyes or skin and can be found in everyday products like **CD players** and **low-power laser pointers**. On the other hand, **Class 2** lasers emit visible light and are safe for accidental exposure. However, direct and prolonged exposure should be avoided. These commonly include **barcode scanners** and **laser pointers designed for demonstrations**.

Moving up the scale, **Class 3** lasers are divided into two subcategories: **Class 3R** and **Class 3B**. Class 3R lasers are potentially dangerous if the eye is deliberately exposed to the beam and include devices such as **laser pointers over 1mW** and **some laser engravers**. Class 3B lasers are more hazardous and can cause immediate eye damage upon direct exposure. These include **higher-powered laser scanners** and **light show projectors**.

| Class | Power | Example Devices |

|---|---|---|

| Class 1 | Safe | CD players, Low-power laser pointers |

| Class 2 | < 1mW | Barcode scanners, Presentation pointers |

| Class 3R | 1 – 5mW | High-power laser pointers, Laser engravers |

| Class 3B | 5 – 500mW | Laser scanners, Light show projectors |

**Class 4** lasers are the most powerful and hazardous. They can cause severe eye and skin injuries upon direct exposure and may also present fire hazards. Proper safety measures, including **safety goggles** and **controlled environments**, are absolutely necessary when operating these devices. You will find Class 4 lasers in **industrial cutting machines** and **professional laser light shows**.

The Dos and Donts of Laser Safety

Ensuring safe usage of lasers requires meticulous attention to both the **dos and don’ts**. One of the cardinal rules is to **always wear appropriate safety gear**. Protective eyewear that matches the specific wavelength of your laser is crucial to prevent ocular damage. Additionally, maintaining a clean, clutter-free workspace helps in managing and minimizing risks effectively.

Respect and awareness of **laser hazard classifications** are essential to staying safe. Here’s a quick reference for understanding the class you’re dealing with:

| Laser Class | Hazard Potential |

|---|---|

| Class 1 | Safe under all conditions of normal use |

| Class 2 | Low power, safe in short exposure |

| Class 3R | Potentially hazardous if viewed directly |

| Class 3B | Hazardous if viewed directly |

| Class 4 | High risk, can cause skin burns and ocular injuries |

**Never** point a laser at reflective surfaces. Doing so can lead to unpredictable reflections that can cause unintended exposure, even in distant areas of the workspace. Similarly, keep your laser device out of reach from children and untrained individuals to avoid accidental activation.

Lastly, ensure you conduct routine maintenance checks and **calibration** of your equipment. Look for signs of wear and tear, such as frayed cables or damaged lenses, and address them promptly. Staying proactive with care can significantly reduce the likelihood of accidents, ensuring a safe and efficient environment for everyone involved.

Creating Safe Work Environments with Laser Equipment

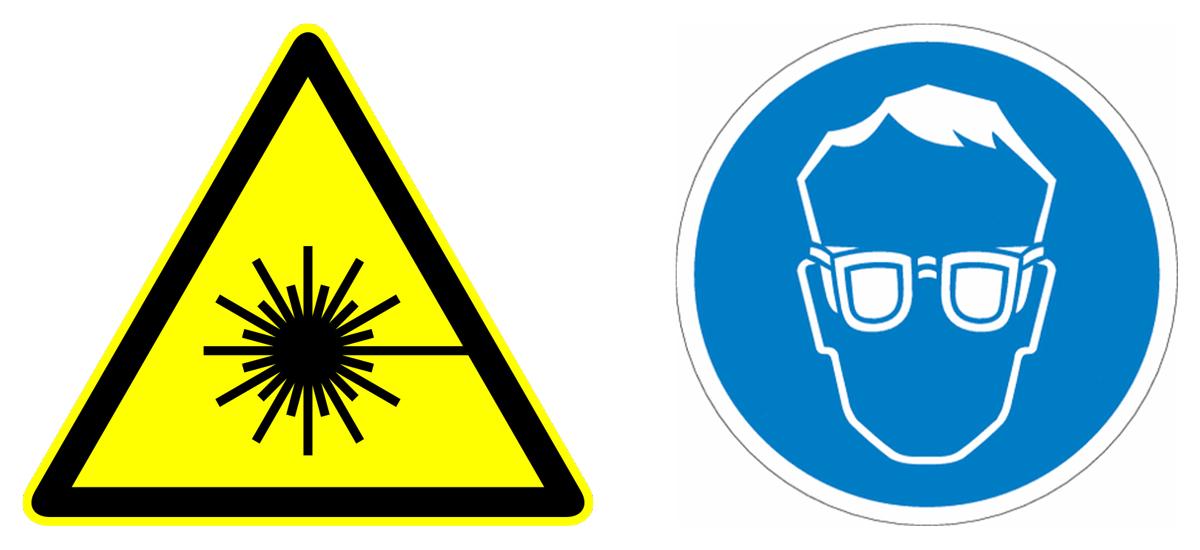

Utilizing laser equipment in work environments requires meticulous risk management and adherence to safety protocols to prevent hazards. One of the initial steps is identifying and demarcating hazard zones. Use signs and barriers to alert personnel to stay clear of these areas. **Access control measures** should be in place to ensure only trained personnel operate near laser machinery. Additionally, implementing clear guidelines and emergency procedures enables quick action if an incident occurs.

- Signage: Use clear, visible signs to identify hazard areas.

- Training: Regularly train staff on safety protocols and equipment usage.

- Barriers: Establish physical barriers around high-risk zones.

- Protective Gear: Ensure availability and use of protective eyewear and clothing.

Understanding and implementing appropriate Laser Safety Standards is critical. Each laser classification comes with distinct requirements, and compliance is non-negotiable. The table below outlines essential safety measures for different classes of lasers, ensuring that proper controls are maintained based on the laser’s potential to cause harm.

| Laser Class | Control Measures |

|---|---|

| Class 1 | Minimal – Generally safe under all conditions. |

| Class 2 | Warning labels and brief exposure avoidance. |

| Class 3 | Protective eyewear; barriers; training. |

| Class 4 | Strict access control; safety interlocks; extensive training. |

Delving into the behavioral aspect, fostering a culture of situational awareness is paramount. Employees should be encouraged to stay vigilant and report any irregularities or potential dangers. Routine audits and safety drills play a significant role in keeping everyone sharp and informed. Emphasizing a collective responsibility towards safe practices not only protects individuals but cultivates a harmonious and productive workplace.

Essential Gear: Protective Eyewear and Beyond

When it comes to working with lasers, protective eyewear is non-negotiable. **Safety glasses or goggles** specifically designed to block or filter laser radiation must be matched correctly to the laser’s wavelength. For instance, a laser that emits in the UV spectrum requires different protection compared to one working in the infrared spectrum. Here’s a quick rundown:

- UV Lasers: Glasses with UV-specific coatings

- Visible Lasers: Tinted lenses that filter specific colors

- Infrared (IR) Lasers: Specialized IR-blocking materials

Beyond eyewear, ensuring your workspace is equipped with additional safety gear is crucial. **Laser barriers**, for example, provide an extra layer of security to contain the laser beam within a designated area. **Appropriate signage** alerts staff and visitors about potential hazards. Moreover, **beam stops** safely absorb or deflect laser beams that stray from their intended path. An effective safety setup can be illustrated as follows:

| Safety Gear | Purpose |

|---|---|

| Laser Barriers | Contain laser beams within safe parameters |

| Appropriate Signage | Alert staff about laser operation zones |

| Beam Stops | Absorb or deflect stray beams |

**Personal protective equipment (PPE)** goes beyond just eyewear. Depending on the laser’s power and type, full-body protective clothing may be necessary. Heat-resistant gloves and face shields can protect against burns from high-intensity lasers. Don’t overlook **ventilation systems**; some lasers can release hazardous fumes or gases, making good air circulation vital for a safe working environment.

Lastly, implementing **laser safety training** for all personnel working in or around laser hazard zones forms the bedrock of a robust safety protocol. Everyone should understand how to identify potential risks, respond to emergencies, and use safety equipment properly. By integrating these precautions and practices, you forge a path to safer and more efficient laser operations.

Managing Laser Accidents: Quick Response and Prevention Tips

Accidents involving lasers can happen in the blink of an eye. The key to effectively managing such incidents is prompt action and preventive preparedness. Here are some essential quick response and prevention tips to ensure safety in environments where lasers are in use:

Immediate Response Steps

- Assess the Situation: Identify the source of the laser and turn it off immediately if it’s still operational.

- Assist the Injured: Administer first aid for burns or eye injuries and call emergency services for serious injuries.

- Secure the Area: Evacuate if necessary and prevent others from entering the vicinity until the area is declared safe.

Prevention Strategies

- Training Programs: Conduct regular training for all personnel to ensure they understand the risks and proper handling of laser equipment.

- Protective Gear: Equip all users with appropriate safety goggles and clothing to protect against laser exposure.

- Clear Labeling: Mark all laser equipment and danger zones with clear signage to prevent unintentional exposure.

Recommended Safety Equipment

| Equipment | Description |

|---|---|

| Laser Safety Glasses | Specialized eyewear designed to protect against specific laser wavelengths. |

| Warning Signs | Visible markers indicating areas where lasers are in use. |

| First Aid Kits | Kits equipped for handling laser-related injuries, including burns and eye care. |

By adhering to these guidelines, the risk of laser accidents can be substantially minimized. Remember, a proactive approach is always the best defense. Regular safety drills, proper equipment handling, and maintaining a culture of awareness are crucial in navigating safety and hazard zones effectively.

Q&A

Q&A: Lasers with Care: Navigating Safety and Hazard Zones

Q: What’s the big deal about laser safety, anyway?

A: Oh, lasers might seem like cool futuristic toys, but they pack a punch that can be pretty serious if not handled with care. Think of them like mini-light sabers—they can do some real damage if aimed recklessly. Proper laser safety ensures we can harness all that awesome power without unwanted side effects like eye injuries or accidental fires. Plus, it keeps everyone in the lab from looking like a scene out of an accident-prone sci-fi movie!

Q: So, what’s the first rule of thumb when working with lasers?

A: It’s like your mama always said—don’t point at anything you don’t intend to destroy! Always be mindful of where your laser is directed and ensure it stays within designated safe zones. And of course, never, ever look directly into the beam. Your eyes will thank you.

Q: What are these ‘safe zones’ you’re talking about?

A: Safe zones are clearly marked areas where the laser can operate without posing a risk to people or property. Think of them like invisible fencing for your beams of light. These zones should be clearly labeled and set up according to regulatory guidelines to prevent accidental exposure.

Q: How do you know if you’re entering a hazardous laser zone?

A: Warning signs and barriers are your best friends here. Hazard zones should be marked with appropriate signage indicating the presence of laser equipment. If you see a warning sign, it’s a sign (literally) to put on your protective gear and proceed with caution.

Q: What kind of protective gear are we talking about?

A: Eye protection is the superstar here! Specially made laser safety goggles can shield your eyes from harmful beams. The type of goggles you need depends on the laser’s wavelength and power, so it’s important to use the correct pair for the job. Think of them as your super-powered safety sunglasses.

Q: Can you share a laser safety horror story?

A: Ah, the tales I’ve heard… Imagine a lab tech who forgot to check if the warning system was operational. A careless glance at a reflected beam led to a significant burn on their retina. A good reminder that even momentary lapses can have long-lasting consequences. That’s why safety protocols exist—for everyone’s well-being.

Q: How can one practice good laser safety habits?

A: Treat every laser like it’s always on, even if it’s not. Always use beam stops, proper enclosures, and reflective barriers. Regularly check your equipment to ensure it’s in good working order, and keep all reflective jewelry and accessories out of the hazard zones. It’s all about creating a safety-first mindset.

Q: What’s the deal with reflected beams and why are they dangerous?

A: Reflected beams can be sneaky—unexpected, and equally harmful. Even a dull reflection from a shiny surface can pose a risk. It’s like playing a game of laser tag where every mirror is an unexpected opponent! To avoid this, maintain a clean workspace and use materials that absorb rather than reflect laser light.

Q: Any final advice for our laser enthusiasts?

A: Respect the laser, but don’t fear it. With the right training, equipment, and mindset, you can safely enjoy all the benefits that lasers bring to science, medicine, and industry. And let’s be honest—how many people get to say they work with frickin’ lasers?

Remember, folks, lasers are as fun as they are powerful, so let’s give them the respect they deserve and always practice safe lasering!

Closing Remarks

As we wrap up our laser journey, let’s remember that while these beams of focused light can etch the stars in our scientific endeavors and creative exploits, they also command a respect as sharp as their precision. By stepping into the world of lasers with the same care we wield them, we transform potential hazards into luminous opportunities. So, whether you’re a seasoned scientist, an enthusiastic hobbyist, or simply an intrigued reader, let’s face our laser-lit path with both curiosity and caution. Here’s to navigating those invisible hazard zones and illuminating our future one safe, brilliant beam at a time. Until next time, stay curious, stay safe, and let your knowledge shine bright! 🌟🔦