When considering the initial investment in a laser machine, it’s important to take into account the cost of the machine itself. Laser machines come in a variety of sizes and capabilities, and the price can vary significantly depending on the specific model and features. Additionally, it’s important to factor in the cost of installation and setup, as well as any necessary training for operators. These costs can add up quickly and should be carefully considered when budgeting for a new laser machine.

In addition to the upfront costs of the machine and installation, it’s also important to consider any additional equipment or accessories that may be needed. For example, some laser machines require specific ventilation or filtration systems to operate safely, and these can add to the initial investment. It’s also important to consider the cost of any necessary software or programming tools that may be required to operate the machine effectively. By carefully considering all of these factors, businesses can make a more informed decision about the initial investment required for a new laser machine.

Key Takeaways

- Initial investment includes the cost of purchasing the laser machine and any necessary accessories or software.

- Total cost of ownership takes into account initial investment, operating costs, and potential resale value.

- Different types of laser machines vary in terms of initial cost, maintenance requirements, and consumable expenses.

- Maintenance and repair costs should be factored in when evaluating the long-term expenses of owning a laser machine.

- Consumables such as laser tubes, lenses, and gases contribute to the overall cost of operating a laser machine.

Evaluating the Total Cost of Ownership

When evaluating the total cost of ownership for a laser machine, it’s important to look beyond just the initial investment and consider the ongoing costs associated with operating and maintaining the machine. This includes factors such as energy consumption, maintenance and repair costs, and the cost of consumables such as laser tubes and lenses. By taking these factors into account, businesses can get a more accurate picture of the long-term costs associated with a laser machine.

Energy consumption is a significant ongoing cost for laser machines, as they require a significant amount of power to operate. It’s important to consider the energy efficiency of different models when evaluating the total cost of ownership, as a more efficient machine can result in lower operating costs over time. Additionally, maintenance and repair costs should be factored in, as all machines require regular maintenance and occasional repairs. Businesses should consider the availability of replacement parts and the cost of service when evaluating the total cost of ownership for a laser machine.

Comparing Different Types of Laser Machines

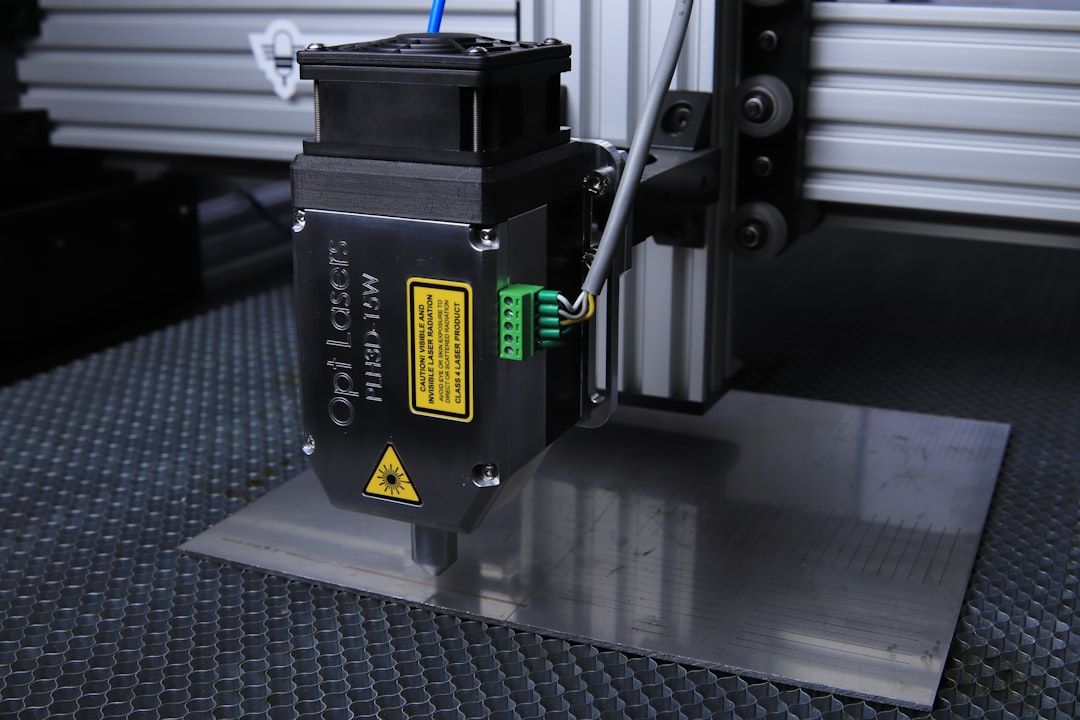

There are several different types of laser machines available on the market, each with its own strengths and weaknesses. CO2 lasers are popular for their versatility and ability to cut through a wide range of materials, while fiber lasers are known for their high precision and speed. Additionally, there are also diode lasers, which are often used for marking and engraving applications. When comparing different types of laser machines, it’s important to consider factors such as cutting speed, precision, and the types of materials that can be processed.

CO2 lasers are often favored for their ability to cut through materials such as wood, acrylic, and plastics, making them a popular choice for businesses in industries such as signage and woodworking. Fiber lasers, on the other hand, are known for their ability to cut through metals with high precision, making them a popular choice for industries such as automotive and aerospace. Diode lasers are often used for marking and engraving applications, offering high-speed processing and fine detail. By carefully considering the specific needs of their business, businesses can make a more informed decision about which type of laser machine is best suited to their needs.

Factoring in Maintenance and Repair Costs

| Vehicle Model | Average Annual Maintenance Cost | Average Annual Repair Cost |

|---|---|---|

| Toyota Camry | 400 | 500 |

| Honda Civic | 350 | 450 |

| Ford F-150 | 600 | 700 |

Maintenance and repair costs are an important factor to consider when evaluating the total cost of ownership for a laser machine. All machines require regular maintenance to keep them operating at peak efficiency, and occasional repairs may be necessary as well. It’s important to consider factors such as the availability of replacement parts and the cost of service when factoring in maintenance and repair costs for a laser machine.

Some manufacturers offer extended warranties or service plans that can help businesses budget for maintenance and repair costs more effectively. By taking advantage of these options, businesses can ensure that their laser machine remains in good working condition without unexpected expenses. Additionally, businesses should also consider factors such as the ease of maintenance and the availability of technical support when evaluating different models of laser machines.

Considering the Cost of Consumables

In addition to the initial investment in a laser machine, businesses should also consider the ongoing cost of consumables such as laser tubes, lenses, and cutting gases. These consumables are necessary for the operation of the machine and can add significantly to the total cost of ownership over time. It’s important to carefully consider these costs when budgeting for a new laser machine.

The cost of consumables can vary significantly depending on factors such as the type of machine and the specific materials being processed. For example, cutting gases such as nitrogen or oxygen are often used in conjunction with laser cutting machines, and the cost of these gases can add up over time. Additionally, laser tubes and lenses have a limited lifespan and will need to be replaced periodically, adding to the ongoing cost of operating a laser machine. By carefully considering these factors, businesses can make a more accurate assessment of the total cost of ownership for a laser machine.

Exploring Financing and Leasing Options

For businesses looking to invest in a new laser machine, there are a variety of financing and leasing options available that can help spread out the initial investment over time. Financing options such as equipment loans or lines of credit can provide businesses with the capital they need to purchase a new laser machine while spreading out the cost over several years. Leasing options are also available, allowing businesses to pay a monthly fee for the use of a laser machine without having to make a large upfront investment.

When exploring financing and leasing options, it’s important to carefully consider factors such as interest rates, repayment terms, and any additional fees or charges that may apply. By comparing different options from multiple lenders or leasing companies, businesses can find the best financing solution for their specific needs. Additionally, businesses should also consider factors such as tax implications and potential resale value when evaluating financing and leasing options for a new laser machine.

Calculating Return on Investment

When investing in a new laser machine, it’s important to carefully calculate the potential return on investment to ensure that the purchase makes financial sense for the business. Factors such as increased production capacity, reduced outsourcing costs, and new revenue opportunities should be taken into account when calculating the potential return on investment for a laser machine. By carefully considering these factors, businesses can make a more informed decision about whether investing in a new laser machine is a financially sound decision.

In addition to direct financial benefits, businesses should also consider factors such as improved product quality, faster turnaround times, and increased customer satisfaction when calculating return on investment for a laser machine. These intangible benefits can have a significant impact on the overall success of the business and should not be overlooked when evaluating the potential return on investment for a new laser machine. By carefully considering both direct financial benefits and indirect business improvements, businesses can make a more accurate assessment of the potential return on investment for a new laser machine.

In conclusion, investing in a new laser machine requires careful consideration of factors such as initial investment, total cost of ownership, different types of machines, maintenance and repair costs, consumables, financing options, and return on investment. By carefully evaluating these factors and making informed decisions, businesses can ensure that they make a sound investment that will benefit their operations in the long run.

If you’re considering investing in a professional laser machine for your business, you may be wondering about the cost. Understanding the financial commitment involved is crucial before making a decision. In a recent article on inlaserhairremoval.com, they delve into the various factors that contribute to the cost of professional laser machines and provide valuable insights for those looking to make this investment. To learn more about the cost considerations and other important aspects of professional laser machines, check out their informative article here.

FAQs

What factors influence the cost of a professional laser machine?

The cost of a professional laser machine can be influenced by factors such as the type of laser technology, the power and capabilities of the machine, the brand and manufacturer, and additional features such as automation and software.

What is the average cost of a professional laser machine?

The average cost of a professional laser machine can range from $10,000 to $100,000 or more, depending on the factors mentioned above.

Are there additional costs associated with owning a professional laser machine?

Yes, there are additional costs to consider such as maintenance, training, consumables (such as laser tubes and lenses), and any necessary upgrades or repairs.

Are there financing options available for purchasing a professional laser machine?

Yes, many manufacturers and distributors offer financing options for purchasing a professional laser machine, which can help spread out the cost over time.

What are some reputable brands and manufacturers of professional laser machines?

Some reputable brands and manufacturers of professional laser machines include Epilog, Trotec, Universal Laser Systems, and Boss Laser. It’s important to research and compare different brands to find the best fit for your specific needs and budget.