Imagine wielding a tool that offers the power to transform everyday materials into intricate works of art, with just the precision of a beam of light. Whether you’re a seasoned maker or a curious beginner, the CO2 laser cutter is an instrument that promises to unlock a world of creative possibilities. In this guide, we’ll embark on a journey through the fascinating realm of CO2 laser cutting, unveiling the secrets behind its astonishing precision and versatility. Ready to light up your creative endeavors? Let’s dive into the magical world of CO2 laser cutters and spark your imagination!

Exploring the Fundamentals of CO2 Laser Cutters

The intrinsic brilliance of CO2 laser cutters lies in their exceptional ability to deliver high-precision cuts through a variety of materials. At their core, these machines harness the power of carbon dioxide to emit a laser beam that is capable of slicing through substances with surgical precision. What makes them particularly appealing to enthusiasts is their versatility and ease of use. Whether you are crafting delicate designs on wood, etching glass, or cutting intricate patterns on acrylic, the CO2 laser cutter delivers impeccable results. Moreover, the technology behind these machines ensures that the edges are clean and smooth, negating the need for any post-processing work.

Key Features of CO2 Laser Cutters:

- **High Precision**: Achieves accuracy within micrometers.

- **Versatility**: Effective on materials like wood, acrylic, metals, and glass.

- **User-Friendly**: Intuitive interfaces that allow even beginners to operate efficiently.

- **Customizability**: Adjustable settings to suit different materials and project needs.

For those keen on understanding the operational facets, here’s a breakdown of the primary components and their functions:

| Component | Function |

|---|---|

| **Laser Tube** | Contains the CO2 gas mixture that generates the laser beam. |

| **Cooling System** | Maintains an optimal operating temperature by dissipating excess heat. |

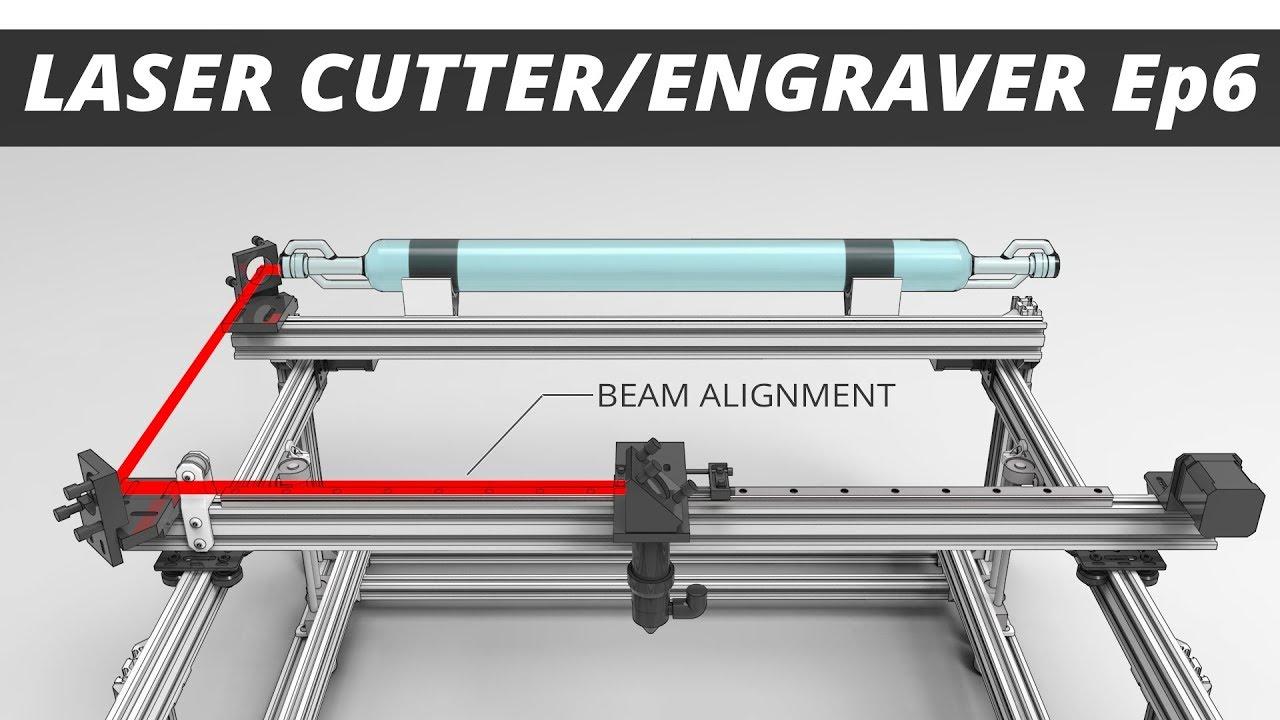

| **Optics** | Mirrors and lenses that direct and focus the laser beam onto the material. |

| **Control Panel** | User interface for adjusting settings and managing the cutting process. |

Maintenance Tips:

- Regularly clean the optics to ensure maximum efficiency.

- Keep the cooling system in check to prevent overheating.

- Calibrate the machine periodically to maintain cutting precision.

- Use the manufacturer’s recommended settings for different materials to prolong equipment life.

The CO2 laser cutter is more than just a tool—it’s a gateway to unlocking unparalleled creativity and precision. By mastering its fundamentals and adhering to best practices, enthusiasts can fully explore its transformative potential. Happy cutting!

Choosing the Right CO2 Laser Cutter for Your Projects

When embarking on your journey to find the perfect CO2 laser cutter, it’s essential to consider the **material types** you’ll work with. Different laser cutters vary in their capabilities to handle various materials, including wood, acrylic, fabric, and even metal. For instance, a machine with a higher wattage will effortlessly slice through thicker materials, whereas a lower wattage might be suitable for more delicate works. Consider creating a list of materials you frequently use and check the laser cutter’s specifications to ensure compatibility. This will save you any future headaches and keep your projects running smoothly.

Another crucial factor is the **size of the working area**. The dimensions of the laser cutter’s bed determine the maximum size of the material you can work with. If you’re planning to tackle larger projects like signage or furniture components, a larger bed will be indispensable. Conversely, for smaller, intricate designs like jewelry or custom stamps, a compact machine might suffice and save valuable space in your workshop.

**Software compatibility** is an often overlooked but vital aspect of choosing a CO2 laser cutter. Ensure that the cutter supports the design software you are comfortable with or are willing to learn. Some popular options include Adobe Illustrator, CorelDRAW, and Inkscape. Additionally, check if the laser cutter comes with its proprietary software and whether it integrates seamlessly with your existing setup. This not only aids in a smoother workflow but also leverages your existing design skills, boosting productivity.

Lastly, don’t forget about the **maintenance and support** aspects. Laser cutters, like any other precision tool, require regular upkeep to ensure longevity and peak performance. Look for models that offer easy access to replaceable parts like lenses and mirrors. Research the manufacturer’s customer support and community forums too. Well-supported devices often come with a wealth of shared user knowledge and troubleshooting tips, which can be invaluable. Here’s a quick comparison to guide you:

| Feature | Ideal For | Example Models |

|---|---|---|

| High Wattage | Thicker Materials | Boss LS-1416, Epilog Fusion |

| Large Bed Size | Large Projects | Glowforge Pro, Trotec Speedy 400 |

| Software Compatibility | Easy Integration | OMTech, Full Spectrum Laser |

| Easy Maintenance | Longevity | K40, Aeon Laser Nova |

Mastering Laser Cutter Settings for Optimal Precision

To achieve pinpoint accuracy with your CO2 laser cutter, understanding and optimizing the settings is key. Begin by experimenting with **speed and power settings**. Higher speeds produce faster cuts but may sacrifice detail, while lower speeds offer meticulous precision ideal for intricate designs. Similarly, adjusting the power level can drastically affect the quality of the cut, with higher power suited for thicker materials and lower power optimal for delicate structures. A balanced approach tailored to your specific material and design needs will yield the best results.

Material choice plays a pivotal role in optimizing your laser cutter settings. Different materials have unique characteristics that can affect the cutting process. Wood, acrylic, and fabric each demand specific speed, power, and focus adjustments. For instance:

- Wood: Lower speed, higher power for clean cuts without burning.

- Acrylic: Moderate speed and power to avoid melting and bubbling.

- Fabric: Very fast speed with low power to prevent fraying edges.

| Material | Speed (mm/s) | Power (%) |

|---|---|---|

| Wood | 20 | 80 |

| Acrylic | 30 | 60 |

| Fabric | 50 | 20 |

Maintaining a clean lens and mirror is as important as the settings themselves. Dust, smoke, and residue can accumulate, causing significant degradation in laser performance and precision. Regularly clean and inspect these components to ensure they remain in pristine condition. Use appropriate cleaning solutions and lint-free cloths to avoid scratches. A well-maintained laser cutter can dramatically extend the lifespan of your machine and deliver consistent, high-quality results.

Lastly, do not overlook the importance of **focus and alignment**. Ensure your laser cutter is properly calibrated; any misalignment can lead to distorted or uneven cuts. Utilize the focus tool that typically accompanies the laser cutter to adjust the focal distance accurately. Align the laser beam perpendicular to the surface to achieve uniform depth across the material. Investing time to set up and fine-tune these aspects will remarkably enhance the precision and efficiency of your projects.

Essential Maintenance Tips for Long-lasting Performance

To ensure your CO2 laser cutter remains in top-notch condition, there are key practices you’ll want to incorporate into your maintenance routine. **Regular cleaning** is vital. Dust and debris can obstruct the laser path and diminish cutting precision. Use a **soft, lint-free cloth** to wipe down the lens and mirrors frequently. For other components, a gentle vacuum helps remove particles that may have gathered in hard-to-reach areas.

| Component | Maintenance Frequency | Tool/Action |

|---|---|---|

| Lens | Daily | Lint-free cloth |

| Mirrors | Weekly | Cleaning solution |

| Rails | Monthly | Lubricant |

Equally important is **checking the alignment** of your laser cutter’s mirrors. Misalignment can lead to skewed cuts and reduced accuracy. Regularly test the alignment by manually moving the laser head to each corner of the cutting area and firing briefly at low power onto a piece of scrap material. Adjust the mirrors accordingly until the beam hits the same spot at each position. Precision in alignment ensures the laser’s path remains optimal.

While the components of your machine work in harmony, they need **consistent lubrication** to keep their motion smooth. Focus on the guide rails and other moving parts. Always use a lubricant specified by your machine’s manufacturer to avoid any undue wear and tear. Think of it like keeping a bicycle chain oiled—every drop counts toward a smoother ride and longer lifespan.

Lastly, pay close attention to your laser cutter’s **cooling system**. The CO2 laser tube generates a significant amount of heat, so maintaining an effective cooling routine is crucial to prevent overheating. Routinely check coolant levels and ensure the cooling system operates efficiently. *Remember, a well-maintained cooling system translates to dependable and extended laser cutter performance.*

Creative Project Ideas for Your CO2 Laser Cutter

Unleash your creativity with your CO2 laser cutter by exploring a variety of engaging projects. Whether you are a seasoned veteran or a newcomer to the world of laser cutting, there’s a wealth of possibilities awaiting you. Here are some inspiring ideas to get those creative gears turning:

- Custom Home Decor: Personalize your living space by creating unique wall art, intricate lampshades, or bespoke coasters. A CO2 laser cutter allows you to etch detailed designs on wood, acrylic, and even fabric, giving your home decor a truly unique touch.

- Bespoke Jewelry: Design and fabricate stunning pieces of jewelry with precision. Use materials like wood, acrylic, or leather to craft earrings, necklaces, bracelets, and more. The possibilities for intricate, custom designs are endless.

- Educational Tools: Create interactive learning aids such as puzzle pieces, anatomical models, and engraved flashcards. These tools can be a great way to make learning fun and engaging for students of all ages.

- Gift Keepsakes: Design memorable, personalized gifts such as photo frames, keychains, and bookmarks. Adding a personal touch through laser-engraved messages or designs makes any gift special.

Not sure where to start? Here’s a helpful table with some simple project ideas to get you on your way:

| Project | Materials | Skill Level |

|---|---|---|

| Custom Coasters | Wood, Cork | Beginner |

| Engraved Keychains | Acrylic, Leather | Intermediate |

| Personalized Lampshades | Fabric, Wood | Advanced |

Let your imagination take the reins and experiment with these project ideas, or dream up entirely new concepts that harness the precision of your CO2 laser cutter. The magic lies in the process of creation, where each cut and etch brings your vision to life. Happy crafting!

Q&A

Q&A: Unlocking Precision with CO2 Laser Cutters

Q1: What exactly is a CO2 laser cutter, and why should I be excited about it?

A1: Ah, the CO2 laser cutter—think of it as the ultimate tool in your crafting arsenal! This miraculous machine uses a high-powered laser beam generated by exciting carbon dioxide gas to slice through materials with surgical precision. Whether you’re a hobbyist, an artist, or a DIY enthusiast, the possibilities are as limitless as your imagination. From creating intricate designs in wood to engraving delicate patterns on acrylic, this tool brings your wildest creative dreams to life with unparalleled accuracy.

Q2: How do I even begin to use a CO2 laser cutter?

A2: Excellent question! Starting your journey with a CO2 laser cutter might seem daunting, but fear not! Begin by choosing the right machine that fits your needs and budget. Once you have your cutter, familiarize yourself with the accompanying software, which is the brain behind the brawn. Load your design into the software, select your material, adjust the settings, and voilà! The laser cutter does the rest, translating your digital designs into tangible masterpieces. Remember, practice makes perfect, so don’t hesitate to experiment and learn as you go.

Q3: Are there specific materials I can work with, and what should I avoid?

A3: Indeed, CO2 laser cutters are incredibly versatile! They love working with a variety of materials, including wood, acrylic, leather, paper, and even some fabrics. However, they do have their limits—avoid using materials that contain chlorine, like PVC, as they can produce toxic fumes and damage your machine. Always refer to the material guidelines provided with your cutter to ensure safe and optimal usage.

Q4: What safety precautions should I keep in mind while using a CO2 laser cutter?

A4: Safety first, always! Here are some essential tips:

- Ventilation: Ensure your workspace has adequate ventilation to avoid inhaling any fumes produced during cutting.

- Eye Protection: Many CO2 cutters come with safety enclosures, but wearing protective eyewear is a good practice.

- Regular Maintenance: Keep your machine clean and well-maintained to prevent malfunctions.

- Fire Safety: Always have a fire extinguisher nearby as a precaution, especially when working with flammable materials.

- Supervision: Never leave the machine running unattended. It’s like leaving a pot on the stove—best to keep an eye on it!

Q5: How can I achieve the best results with my CO2 laser cutter?

A5: Oh, the sweet satisfaction of a perfectly cut design! To achieve top-notch results:

- Settings Matter: Tweak the power, speed, and frequency settings according to the material you’re using.

- Focus and Alignment: Ensure the laser is properly focused and aligned for sharp, clean cuts.

- Test Runs: Conduct small test runs on scrap pieces of your material to fine-tune the settings before starting your final project.

- Clean Lens and Mirrors: Regularly clean the lens and mirrors of your cutter to maintain laser efficiency and precision.

- Patience and Practice: Mastery takes time, so be patient and keep practicing!

Q6: Can you recommend some projects I can start with my CO2 laser cutter?

A6: Absolutely! Here are a few fun and inspiring project ideas to get your creative juices flowing:

- Customized Coasters: Personalize coasters with intricate patterns or names—great for gifts or personal use.

- Decorative Wall Art: Cut out beautiful, unique wall hangings from wood or acrylic.

- Engraved Jewelry: Create stunning, personalized pendants, earrings, or bracelets.

- Model Kits: Craft detailed model kits from plywood—ideal for building miniature houses, airplanes, or vehicles.

- Home Decor: Make stylish and functional items like lampshades, clock faces, or even custom furniture accents.

So, ready to unleash your inner creativity with a CO2 laser cutter? Dive in and watch your ideas materialize with spectacular precision and flair!

Final Thoughts

As we draw the curtain on this enlightening journey through the realm of CO2 laser cutters, it’s clear that the marriage of precision and creativity is truly a match made in maker heaven. With every sizzling slice and intricate etch, these remarkable machines unlock endless possibilities for enthusiasts like you, who dare to transform the ordinary into the extraordinary.

No matter where you are on your crafting voyage, remember that mastering the art of CO2 laser cutting is as much about exploration as it is about skill. Every project you undertake, every little adjustment you make, is a step towards perfecting your craft and breathing life into your wildest imaginings.

So, gear up and let that spark of passion guide you. Share your creations, inspire others, and most importantly, have fun while wielding the power of laser precision. The world of CO2 laser cutting is vast and full of potential, waiting for you to leave your indelible mark. Keep cutting, keep dreaming, and keep pushing the boundaries of what’s possible. Until next time, happy creating!